Why Standard Solutions Fall Short

Every manufacturing system presents unique challenges. So why compromise performance with one-size-fits-all tubing? In today’s demanding electrical applications — from high-voltage battery systems to precision motor assemblies — standard catalog products increasingly fall short of meeting the complex performance requirements that engineers face. Custom electrical insulation tubing represents not just an alternative, but often the optimal solution for applications requiring specific combinations of electrical, thermal, mechanical, and chemical properties that off-the-shelf products simply cannot deliver.

Engineering Custom Tubing Solutions is Our Specialty: Connect with Electrolock’s team to explore how spiral wound tubing can solve your most demanding insulation challenges.

The Four Critical Questions That Drive Custom Solutions

At Electrolock, we’ve learned that successful electrical insulation tubing begins with understanding your specific application requirements. Our engineering approach centers on four essential questions that guide the development of optimal solutions:

How Will the Tube Be Used?

Application context determines everything. Battery cell insulation demands different properties than motor lead protection or busbar covering. Understanding the operational environment, voltage levels, and thermal conditions allows us to recommend materials and constructions that align precisely with your needs. Whether protecting high-voltage connections in electric vehicles or insulating sensitive electronics, the application drives material selection.

What Are the Performance Requirements?

Defining performance specifications requires examining multiple properties simultaneously. Electrical requirements include voltage breakdown resistance and dielectric strength — critical factors addressed by industry standards like UL 224, the Standard for Extruded Insulating Tubing. Thermal properties encompass operating temperature ranges, flame ratings, and thermal conductivity. Mechanical demands cover tensile strength, tear resistance, and puncture protection. Chemical considerations include resistance to oils, solvents, and process chemicals. Custom tubing allows optimization across all these dimensions rather than accepting the compromises inherent in standard products.

How Will It Be Installed?

Manufacturing integration significantly impacts tubing selection. We can provide spiral wound tubing in configurations that streamline your production process: cut-to-length parts for manual assembly, continuous rolls for automated equipment, flared ends for easier installation, sealed end caps for moisture protection, or notched cuts for specific geometric requirements. These customizations reduce installation time, minimize errors, and improve overall manufacturing efficiency.

What’s the Budget?

Cost-effectiveness means delivering required performance at an optimal price point, not simply choosing the cheapest option. Our extensive materials knowledge allows us to engineer solutions that meet specifications without over-engineering. Sometimes, a carefully designed composite structure combining materials like PET film, fiberglass backing, and mica layers delivers better value than expensive single-material alternatives. Meeting your cost requirements is as important as meeting your performance requirements.

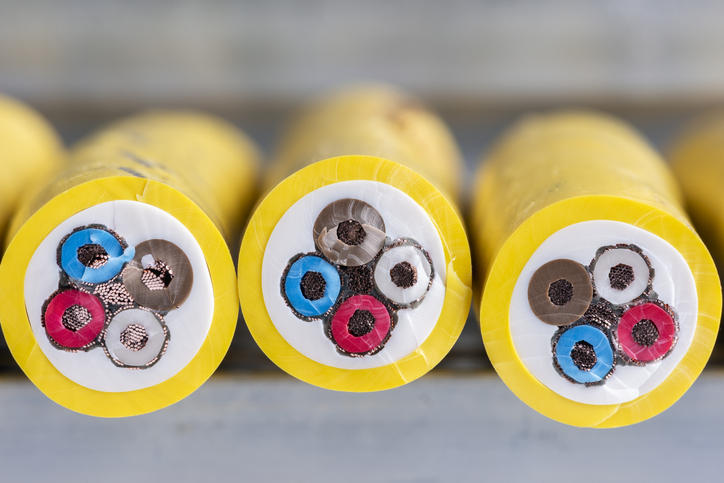

Material Flexibility Enables Optimal Solutions

The versatility of spiral wound tubing construction allows selection from a broad materials palette. Options include PET (polyester) for cost-effective applications with moderate temperature requirements, Kapton® (polyimide) for extreme temperature endurance, Nomex® (aramid paper) for exceptional mechanical strength, fiberglass for dimensional stability, mica for superior dielectric properties and thermal resistance, and specialized materials like PEEK or Ultem® for demanding chemical environments. We often combine multiple materials in laminated structures, creating tubing that delivers properties no single material could provide alone.

Dimensional flexibility further enhances customization possibilities. Wall thickness ranges from 0.002″ for space-constrained applications to 0.125″ for robust protection. Inside diameters span from 0.050″ for fine wire insulation to 6.0″ for large busbar covering. Length options include short cut pieces, extended lengths, or continuous rolls, depending on your manufacturing process.

The Engineering Partnership Beyond Product Delivery

Custom electrical insulation tubing development extends beyond simply supplying materials. Electrolock’s comprehensive testing capabilities validate that selected solutions perform reliably under your specific operating conditions. We can conduct dielectric strength testing, thermal cycling analysis, mechanical property verification, and chemical resistance evaluation — ensuring materials meet both immediate performance needs and long-term reliability requirements. This validation prevents costly failures and redesigns.

Our engineering support continues through production implementation. We work directly with your manufacturing team to optimize tubing configurations for efficient processing, minimize waste, and ensure consistent quality. Whether developing shrink-tubing applications, non-shrink protective sleeves, or specialty constructions, our goal remains building success from the inside out — recognizing that while insulation remains hidden, it makes all the difference to system performance and safety.

Partner With Electrical Insulation Tubing Specialists

When off-the-shelf products cannot meet your application’s unique demands, custom spiral wound tubing provides the engineering solution. With over 65 years of materials expertise, Electrolock approaches each project by asking the right questions, understanding your specific requirements, and developing tubing solutions optimized for both performance and manufacturing efficiency.

Contact our engineering team to discuss how custom electrical insulation tubing can enhance the reliability and efficiency of your electrical systems.