Choosing the Right Tubing Solution for Your Electrical Applications

When selecting industrial insulation solutions for electrical applications, procurement professionals often face a choice between lay flat tubing and spiral wound tubing. Both options provide reliable protection for wires, cables, and battery components, but each offers distinct advantages depending on your specific application requirements. Understanding these differences helps ensure optimal performance while managing costs effectively.

Custom Solutions for Your Specific Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

Understanding the Fundamental Differences

Lay flat tubing represents a flexible, thin-walled solution that stores flat when not in use, offering advantages in storage efficiency and automated manufacturing systems. The flattened configuration allows for efficient processing in high-volume production environments, making it particularly valuable for applications requiring streamlined installation processes.

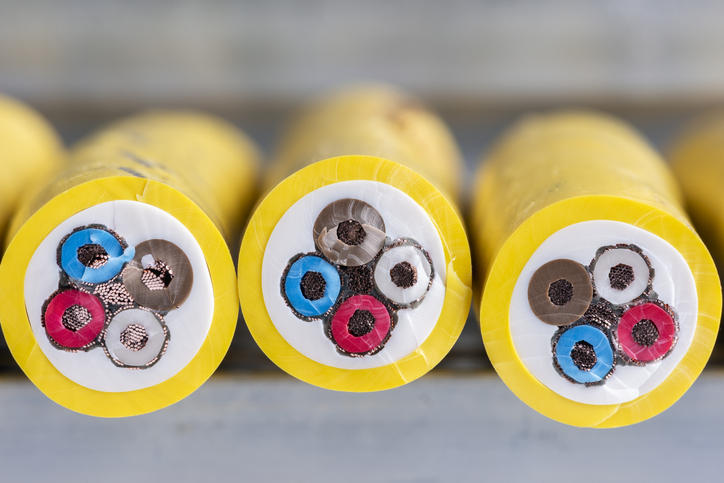

Spiral wound tubing, conversely, provides a more robust construction method where materials are wound in overlapping layers to create customizable wall thicknesses and performance characteristics. This construction approach enables engineers to precisely tailor insulation properties to meet specific application demands.

Application Suitability: Where Each Solution Excels

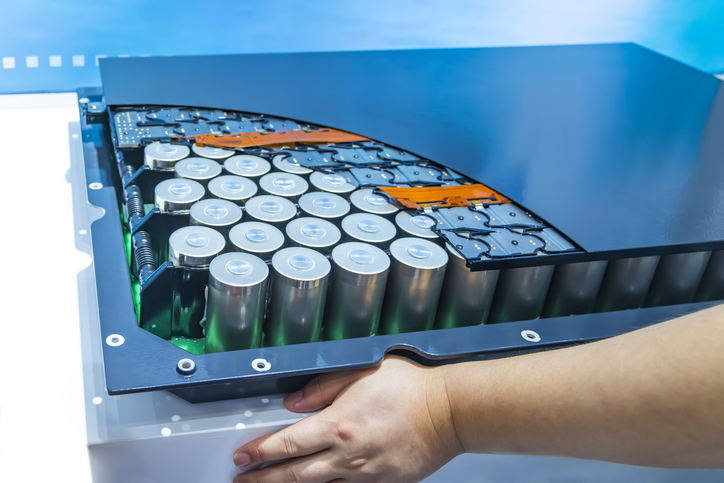

Battery and Electronics Applications

For battery insulation applications, lay flat tubing proves particularly effective in providing jelly roll insulation and tab protection. The thin-wall capability and space-efficient design maximize energy density in constrained battery packs. PET-based lay flat solutions like Electrolock’s 740 HS deliver excellent dielectric protection while maintaining compatibility with automated manufacturing processes.

However, spiral wound tubing offers superior versatility when applications require specific performance combinations. The ability to incorporate multiple materials — such as aramid, polyimide, or specialized barrier films — into a single tube structure provides enhanced protection against multiple threats simultaneously.

Industrial and Power Generation Uses

In demanding industrial environments, spiral wound construction demonstrates clear advantages. The multi-layer approach enables the integration of materials with complementary properties: outer layers might provide chemical resistance while inner layers focus on dielectric strength. This flexibility proves particularly valuable in high-voltage applications where complex performance requirements demand engineered solutions.

Lay flat tubing, while effective for standard protection needs, typically serves better in applications where simplicity and cost-effectiveness take precedence over multi-faceted performance requirements.

Installation and Manufacturing Considerations

Production Line Integration

Lay flat tubing excels in automated manufacturing environments. The flattened storage configuration reduces shipping costs and simplifies handling systems. When expanded during installation, the tubing provides complete encapsulation with minimal operator intervention. This characteristic makes lay-flat solutions particularly attractive for high-volume production scenarios where labor efficiency impacts overall costs.

Spiral wound tubing requires more consideration during installation planning. However, this investment in setup complexity pays dividends through enhanced customization options. Electrolock’s spiral wound solutions can be supplied with specialized features, including notched cuts, sealed end caps, and custom dimensions that integrate seamlessly into specific manufacturing processes.

Customization Capabilities and Industrial Insulation Solutions

Material Flexibility

Both tubing types accommodate various materials, but spiral wound construction offers broader customization potential. While lay flat tubing typically utilizes PET or PVC formulations, spiral wound systems can incorporate diverse material combinations, including Nomex®, Kapton®, fiberglass, and specialized barrier films within a single tube structure.

This flexibility enables spiral wound solutions to address complex application requirements — such as simultaneous electrical insulation, thermal management, and chemical resistance — that might otherwise require multiple separate components.

Dimensional Options

Lay flat tubing provides excellent options for thin-wall applications, with capabilities as low as 0.002″ wall thickness. This characteristic proves valuable when space constraints demand minimal insulation bulk while maintaining electrical protection.

Spiral wound construction offers broader dimensional flexibility, accommodating wall thicknesses from 0.002″ to 0.125″ and inside diameters ranging from 0.050″ to 6.0″. This range enables precise matching to specific application requirements while maintaining the structural integrity that multi-layer construction provides.

Making the Right Choice for Your Application

When evaluating these industrial insulation solutions, consider your primary requirements:

Choose lay flat tubing when:

- Cost-effectiveness takes priority

- Applications involve high-volume, automated assembly

- Space constraints demand minimal wall thickness

- Standard electrical insulation requirements are sufficient

Select spiral wound tubing when:

- Applications demand multiple performance characteristics

- Custom material combinations provide value

- Installation flexibility justifies additional complexity

- Long-term reliability in demanding environments is critical

The Right Industrial Insulation Solutions Require Engineering Support

Regardless of which solution better fits your initial requirements, working with experienced insulation specialists ensures optimal results. Electrolock’s comprehensive engineering support includes material selection guidance, custom sizing specifications, and validation testing to ensure performance reliability throughout your product’s lifecycle.

Contact Electrolock today to discuss how our engineered tubing solutions — whether lay flat or spiral wound — can enhance the reliability and efficiency of your industrial insulation applications.