Engineering Excellence for High-Voltage Protection Where Standard Materials Falter

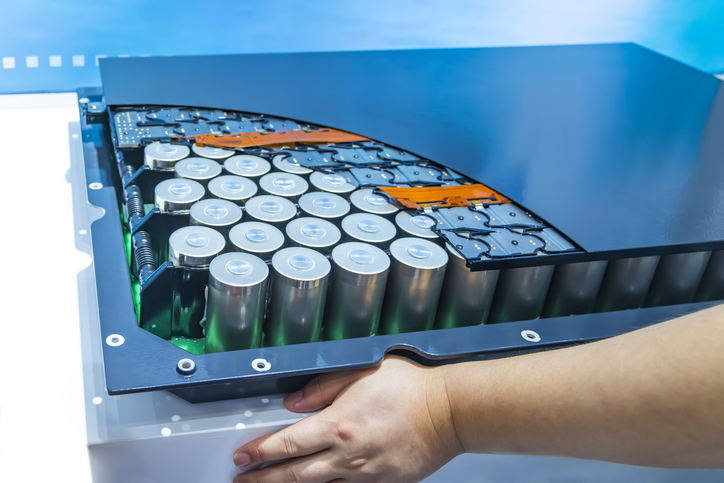

In large generators and high-voltage stator coils, insulation is constantly under pressure — literally. These systems endure immense mechanical stress, high operating temperatures, and the constant risk of catastrophic electrical shorts that can result in costly generator failures and extended downtime. At critical points, like the crossover areas in Roebel bars where conductors transition positions, insulation materials have to do more than just resist heat — they must stand up to intense puncture forces, shear stress, and long-term mechanical wear. That’s where advanced Kevlar® insulation products excel.

Since 1957, Electrolock has been building success from the inside out, understanding that what you can’t see often makes all the difference in system reliability. Our Keveloc® and Kevenex® offerings represent this commitment to engineering excellence — specialized solutions engineered specifically to enhance durability and cut-through resistance in the most demanding applications. By combining the exceptional strength properties of Kevlar with Electrolock’s decades of insulation expertise, these precision-engineered laminates offer protection exactly where it matters most.

Custom Solutions for Your Specific Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

Why Kevlar for Critical Electrical Insulation Applications?

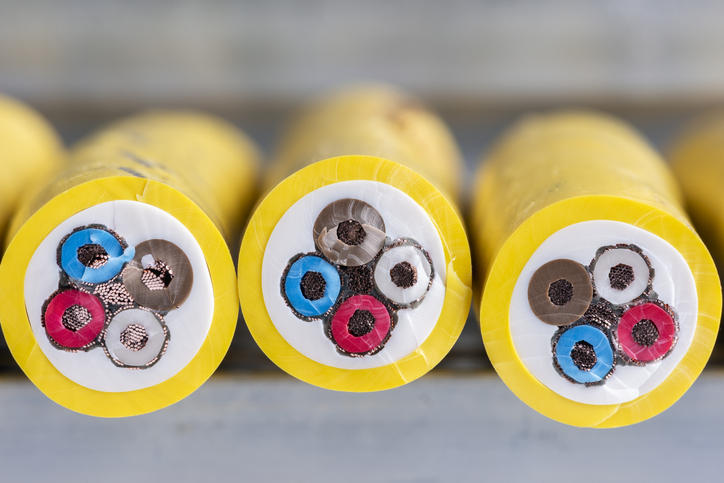

Kevlar is renowned for its role in protective gear and high-strength composites, but its unique properties are equally valuable in electrical insulation applications where failure is prohibitively expensive. With exceptional tensile strength and superior resistance to puncture, Kevlar laminates act as a reliable barrier against turn-to-turn shorts, particularly at crossover points where conductors overlap and mechanical stress concentrates to levels that can compromise standard insulation materials.

In the precision manufacturing process of VPI stator coils and bars, these barrier inserts are strategically applied during pre-consolidation phases, ensuring long-term circuit integrity and dramatically reducing the risk of costly downtime or equipment failure that can cascade into major operational disruptions.

Keveloc: Engineered for Maximum Strength and Uncompromising Reliability

Keveloc is precision-designed for the most demanding applications, where insulation faces extreme compression and shear forces that would destroy conventional materials. With impressive technical specifications including a tensile strength of 175 pounds per inch width and an exceptional shear puncture rating of 1,381 pounds, Keveloc provides a formidable barrier that resists cut-through even in the most punishing operating conditions.

At just 0.015 inches thick, it adds robust mechanical protection without compromising coil design constraints or electromagnetic performance. Engineered for Class F or Class H machines with thermal ratings that can handle operating temperatures up to 180°C, Kevoloc proves ideal for crossover barriers in Roebel conductors and other high-voltage applications where thermal and mechanical stresses combine. For operators managing critical power generation assets, this translates to dependable durability and proven protection against turn-to-turn shorts precisely where failure is most likely to occur and cause maximum damage.

Kevenex: Flexible Engineering and Customizable Protection Solutions

Kevenex delivers many of the same advanced protective benefits as Kevoloc, but is specifically optimized for Class F machine applications where thermal requirements and operating conditions demand tailored solutions. It provides reliable puncture resistance under compression and shear stress, making it exceptionally well-suited for use as a crossover barrier in VPI stator coils and bars during critical pre-consolidation manufacturing phases.

One of Kevenex’s key engineering advantages is its exceptional customization flexibility. It can be manufactured to customer-specified widths, lengths, or complex shapes, ensuring seamless integration into unique coil designs and geometric requirements. This precision customization capability allows engineers to adapt insulation solutions to their exact specifications without compromising protective performance or manufacturing efficiency.

Stronger Together: Strategic Use of Kevoloc and Kevenex in Combination

While both materials demonstrate exceptional performance independently, Electrolock’s engineering expertise often recommends using them together to provide comprehensive layered protection across different stress points within the same system. By strategically combining Kevoloc’s superior tensile and puncture resistance with Kevenex’s adaptable design capabilities, insulation systems gain added assurance against mechanical wear and electrical failure modes.

This engineered approach reflects our deep understanding of how different areas within high-voltage systems experience varying stress profiles. The result is dramatically improved long-term reliability, reduced maintenance requirements, and extended equipment service life — all of which translate into substantial cost savings and fewer unplanned outages for operators managing critical power infrastructure.

Optimize Kevlar Insulation With Advanced Materials Engineering

When it comes to protecting high-voltage coils and bars in mission-critical applications, standard insulation simply isn’t sufficient for the demands of modern power generation. Kevlar-based solutions like Kevoloc and Kevenex provide the essential cut-through resistance, thermal stability, and mechanical durability needed to withstand punishing mechanical and electrical stresses that define today’s high-performance electrical systems.

Electrolock continues to lead in developing specialized insulation solutions for demanding applications, leveraging our extensive materials engineering expertise to help customers maintain peak performance and uncompromising reliability where failure is not an option. Our commitment to building success from the inside out means understanding the critical details that make the difference between reliable operation and costly failures.

Contact Electrolock today to discuss how Kevoloc and Kevenex can be precisely tailored to meet your specific insulation requirements and enhance the durability of your high-voltage systems.