In electrical engineering, selecting the appropriate insulation materials is critical for ensuring system safety, performance longevity, and manufacturing efficiency. Lay flat tubing represents one of the most versatile and effective solutions for protecting electrical components across various applications, particularly in battery systems, electric vehicles, and sensitive electronics. Let’s take a closer look.

Custom Solutions for Your Specific Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

What Is Lay Flat Tubing?

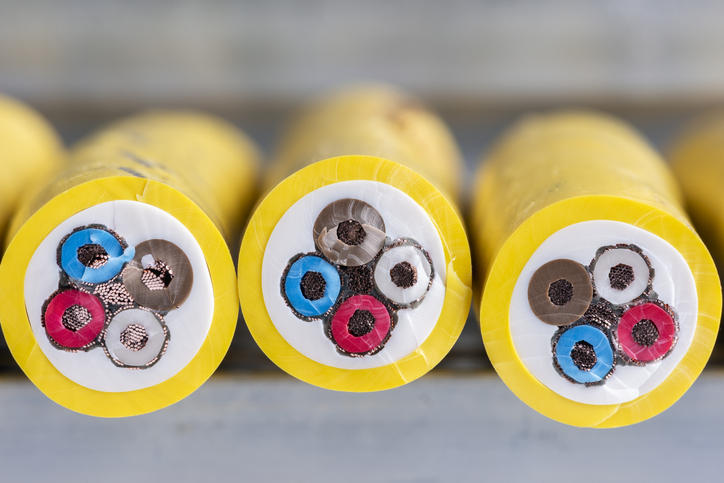

Lay flat tubing is a flexible, thin-walled insulation solution that, as the name suggests, can be stored flat when not in use. This configuration offers advantages in storage efficiency and ease of handling compared to rigid or spiral wound tubing options, while providing excellent protection when deployed. The flattened configuration allows for efficient processing in automated manufacturing systems, making it ideal for high-volume production environments. When applied to components, the tubing can be expanded to completely encapsulate wires, batteries, connections, or other elements requiring protection.

Material Options: PET and PVC

Polyethylene Terephthalate (PET)

PET-based lay flat tubing provides an excellent balance of electrical and mechanical properties, making it suitable for a wide range of applications. This material offers good dielectric strength combined with excellent mechanical durability and chemical resistance. PET tubing is particularly valuable in battery applications requiring cost-effective, reliable insulation with moderate temperature requirements.

- High Dielectric Strength: Provides excellent electrical insulation properties, critical for medium voltage environments

- Temperature Performance: Shrinks at approximately 60°C, making it suitable for automated manufacturing processes

- Thin Wall Capability: Can be manufactured with extremely thin walls (as low as 0.002″), maximizing space efficiency in compact designs

- Abrasion Resistance: Offers excellent mechanical durability against wear and physical stress

- Low Moisture Absorption: Maintains insulation integrity in humid operating conditions

At Electrolock, our PET layflat tubing is represented most often in our 740 HS product offering.

This lineal seal tubing comes as heat shrink sleeves with an extremely thin wall that provides both dielectric protection and physical toughness. 740 HS tubing is composed of a one-sided, anti-static treated modified polyester (PET) film that is clear in color but can be printed on or colored. Formed into tubing, 740 heat shrink sleeves shrink quickly — roughly in 10 seconds at 100°C — and uniformly around cylindrical shapes.

Polyvinyl Chloride (PVC)

PVC lay flat tubing offers exceptional flexibility and resistance to oils, acids, and many solvents. Its dielectric properties make it an excellent choice for applications requiring protection against electrical shorts and interference. PVC tubing is often selected for environments where chemical exposure is a concern.

- Moderate Dielectric Strength: Suitable for standard voltage applications

- Chemical Resistance: Good protection against common solvents and chemicals

- Flexibility: Maintains pliability even at lower temperatures

- Cost-Effectiveness: Provides reliable performance at a lower price point

- Customization Options: Available in numerous colors for identification and coding purposes

Critical Applications Using Lay Flat Tubing

Battery Insulation

In modern battery systems, lay flat tubing plays a crucial role in preventing cell-to-cell shorts and enhancing overall pack safety. PET tubing is particularly valuable in these applications due to its:

- Ability to provide complete coverage for jelly roll insulation

- Superior dielectric protection for tab and lead insulation

- Compatibility with automated manufacturing processes, reducing the risk of foreign object debris (FOD)

- Space-efficient design that maximizes energy density in constrained battery packs

Electric Vehicle Components

Lay flat tubing protects critical wiring harnesses, busbars, and high-voltage connections from thermal stress, vibration, and potential moisture exposure. The tubular design allows for complete encapsulation of sensitive components while maintaining flexibility for complex routing requirements.

- Protection for high-voltage busbars and connections

- Insulation for wire harnesses in crowded EV component assemblies

- Heat-shrink application that creates tight, secure seals against moisture and contaminants

- Flame-retardant options that enhance overall vehicle safety

Electronics and RTD Sensors

For sensitive electronic components like Resistance Temperature Detectors (RTDs), lay flat tubing delivers targeted protection:

- Precise, uniform coverage that maintains sensor accuracy

- Excellent dielectric properties that prevent signal interference

- Thin-wall designs that minimize thermal insulation effects on temperature readings

- Clean installation without adhesive residues that could affect sensitive electronics

Find Exactly What You Require: Explore our power generation product table to view insulation solutions across the spectrum.

Explore Electrolock’s Custom Solutions

With over 65 years of experience in electrical insulation technologies, Electrolock approaches lay flat tubing with an engineering mindset tailored to each client’s specific requirements. Our comprehensive services include:

- Material selection guidance based on application-specific performance needs

- Custom sizing and wall thickness specifications

- Color-coding and custom printing capabilities for component identification

- Quality testing and validation to ensure performance reliability

- Full manufacturing support from prototyping through high-volume production

Understanding that each application presents unique challenges, our team works directly with clients to develop insulation solutions that optimize both performance and manufacturing efficiency.