Turn Complex Requirements Into Optimized Insulation Systems

Not every electrical insulation challenge fits neatly into standard product categories. When applications demand specific combinations of thermal performance, dielectric strength, mechanical durability, and dimensional constraints — often within tight manufacturing tolerances and cost parameters — custom electrical insulation becomes essential rather than optional. These situations signal the need for an engineering partner rather than simply a product supplier.

Standard products fail when geometric complexity demands precise conformability, when multiple performance requirements conflict, when extreme operating conditions exceed catalog specifications, or when manufacturing processes require specialized configurations. If your application involves any of these challenges, custom electrical insulation development offers the pathway to best-fit solutions.

Partner With Engineering Experts: Connect with Electrolock’s team to begin developing custom electrical insulation solutions engineered specifically for your application requirements.

Discovery: Understanding Your Complete Requirements

Effective custom electrical insulation development begins with application analysis. This discovery phase examines not just the obvious specifications, but the complete operational context that influences insulation performance.

Environmental factors include operating temperature ranges, exposure to chemicals or moisture, voltage levels, stress distribution, mechanical loading and vibration, and thermal cycling patterns. Performance requirements encompass dielectric strength needs, thermal management objectives, mechanical property demands, flame resistance specifications, and dimensional tolerances. Manufacturing considerations address installation methods, automation compatibility, production volume implications, and quality verification procedures.

This thorough discovery prevents the costly mistakes that occur when insulation solutions address only partial requirements. Understanding the complete picture, including constraints that may seem secondary but prove critical during implementation, enables the development of solutions that perform reliably throughout their service life.

Engineering: Translating Requirements Into Solutions

With requirements clearly defined, the engineering phase translates specifications into practical insulation system designs. This process draws upon extensive materials knowledge, proven design methodologies, and comprehensive testing capabilities.

Material selection for custom electrical insulation systems requires balancing multiple properties simultaneously. According to UL 1446, electrical insulation systems comprise unique combinations of materials verified for chemical compatibility when used at certain maximum temperatures. Engineers must consider not only individual material properties but also how components interact within the complete system.

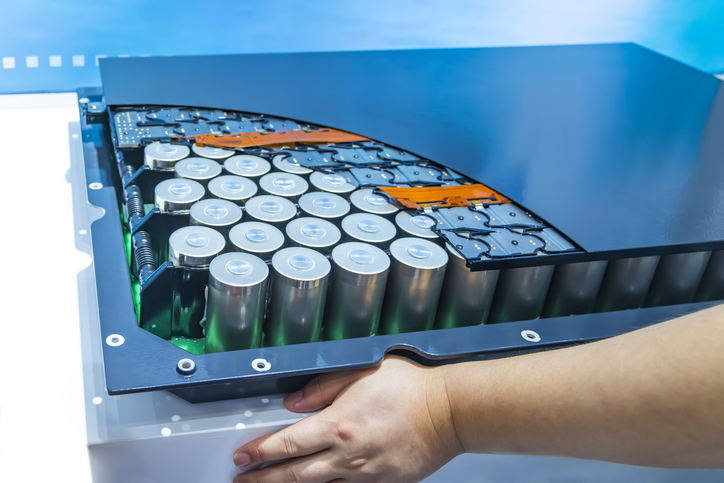

Solution design services integrate material expertise with application knowledge. For battery insulation applications, this might involve combining materials for dielectric protection, thermal management, and mechanical support within extremely tight dimensional envelopes. For high-voltage applications, the design addresses voltage stress distribution, partial discharge resistance, and thermal stability. For specialty spiral wound tubing, engineers optimize layer configurations, dimensional specifications, and end-finish details.

Testing and validation confirm that proposed solutions meet specifications under actual operating conditions. Comprehensive analytical testing examines thermal properties, electrical characteristics, mechanical behavior, and chemical resistance. High-voltage testing validates dielectric performance, partial discharge inception levels, and voltage endurance. This empirical validation prevents failures that theoretical analysis alone cannot predict.

Implementation: From Prototype to Production

Successful custom electrical insulation development extends beyond design. It also requires seamless transition into manufacturing. Implementation phase services ensure solutions that perform excellently in testing also succeed in production environments.

Manufacturing services transform engineered designs into production-ready components. Capabilities include precision slitting and rewinding for exact dimensional control, coating and saturation for enhanced performance properties, laminating for composite structures, and punching or rotary die cutting for complex geometries. These converting processes adapt materials to specific application requirements while maintaining the quality standards essential for reliable insulation performance.

Production implementation also addresses practical manufacturing considerations. Custom configurations might include cut-to-length parts for manual assembly operations, continuous rolls for automated equipment, specialized packaging for contamination-sensitive applications, or quality documentation for traceability requirements. These details — often overlooked until production begins — significantly impact manufacturing efficiency and final product quality.

Quality assurance throughout production ensures consistent performance. Statistical process controls, dimensional verification, electrical testing protocols, and material certification documentation provide confidence that production components match prototype performance. This consistency proves critical in applications where insulation failures create safety risks or operational disruptions.

Explore the Breadth of Custom Insulation Possibilities

Custom electrical insulation development addresses diverse application requirements across multiple industries. Solutions span from precision battery cell insulation in consumer electronics to robust high-voltage systems in industrial power generation. Each application category presents unique engineering challenges requiring specialized material knowledge and design expertise.

The common thread connecting these varied applications is the engineering approach: thorough requirements understanding, thoughtful material selection, rigorous testing and validation, and careful production implementation. This methodology applies whether developing thermal management solutions, optimizing dielectric systems, or engineering mechanical protection.

Integrated Expertise: Where Engineering Meets Manufacturing Excellence

Developing optimal custom electrical insulation requires integrated capabilities rarely found in single organizations. Material expertise without testing facilities produces untested theories. Testing capabilities without manufacturing services creates designs that cannot be produced economically. Manufacturing excellence without engineering support yields components that may not address actual application needs.

Electrolock’s 65 years of experience across battery insulation, high-voltage systems, thermal management, and specialty configurations provides the comprehensive foundation for successful custom development. From initial consultation through production implementation, this integrated approach delivers solutions optimized for both performance and manufacturability.

Begin your custom electrical insulation development with engineering partners who understand that optimal solutions require more than just good materials — they demand extensive capabilities, rigorous methodology, and collaborative partnership.