A Proven Material for Engineers Who Can’t Afford Compromise

For over a century, mica sheet insulation has remained one of the most reliable materials for managing extreme electrical and thermal demands. Its unique combination of dielectric strength, thermal stability, and mechanical durability makes it indispensable across industries where insulation failure isn’t an option. From high-voltage motors spinning in power generation facilities to battery packs powering electric vehicles, mica sheet insulation continues to prove its value in applications where performance and safety are non-negotiable.

At Electrolock, we’ve spent decades engineering mica-based solutions that leverage this material’s exceptional properties. Whether you need ground wall insulation for a 15kV generator, thermal barriers for industrial furnaces, or custom CNC-machined components for specialized equipment, mica sheet insulation provides the foundation for reliable, long-lasting performance.

Solutions Engineered for Your Application: Contact Electrolock to discuss insulation challenges and mica sheet insulation options tailored to your requirements.

What Makes Mica Sheet Insulation Exceptional

Understanding why mica performs so well requires looking at its fundamental properties. Mica is a naturally occurring mineral with a layered crystalline structure that can be processed into thin, flexible sheets or rigid plates. This structure provides mica with several characteristics that complement the goals of insulation solutions.

Superior dielectric strength allows mica sheet insulation to withstand high voltage stress without breaking down. In high-voltage electrical applications, this translates to reliable insulation that maintains its protective properties over years of continuous operation, even under electrical stress that would degrade polymer-based alternatives.

Exceptional thermal stability means mica maintains its structure and insulating properties at temperatures where most materials would fail. While many insulation materials begin degrading above 200°C, mica sheet insulation remains stable at temperatures exceeding 1,000°C. This makes it ideal for applications involving sustained high heat or thermal events where insulation must continue functioning.

Natural flame resistance provides an additional safety margin. Unlike polymer insulations that melt, burn, or release toxic gases when exposed to fire, mica maintains its barrier properties during thermal events. This characteristic proves critical in fire-survival applications where circuit integrity can mean the difference between controlled shutdown and catastrophic failure.

High-Voltage Insulation for Motors, Generators, and Coils

In medium- and high-voltage rotating machinery, insulation integrity directly determines equipment reliability and service life. Electrolock engineers mica-based insulation systems specifically for these demanding applications, including ground wall tapes that provide the primary electrical barrier between coil windings and grounded stator cores, interturn insulation that prevents breakdown between adjacent coil turns, and precision CNC-machined rotor and stator components that ensure exact fit and optimal performance.

The mica tapes used in these systems typically combine mica paper with backing materials like polyester film or fiberglass, creating composites that balance electrical performance with mechanical durability. When properly applied and cured with compatible resin systems, these tapes create robust insulation systems capable of withstanding both electrical stress and mechanical forces during operation.

Thermal Management and Fire-Resistant Solutions

Beyond electrical insulation, mica sheet insulation excels in thermal management applications where heat control is critical. Engineers specify mica-based materials for heat shields that protect sensitive components from radiant heat in industrial equipment, thermal barriers between hot and cold zones in furnaces and kilns, and structural insulating plates that maintain dimensional stability at elevated temperatures.

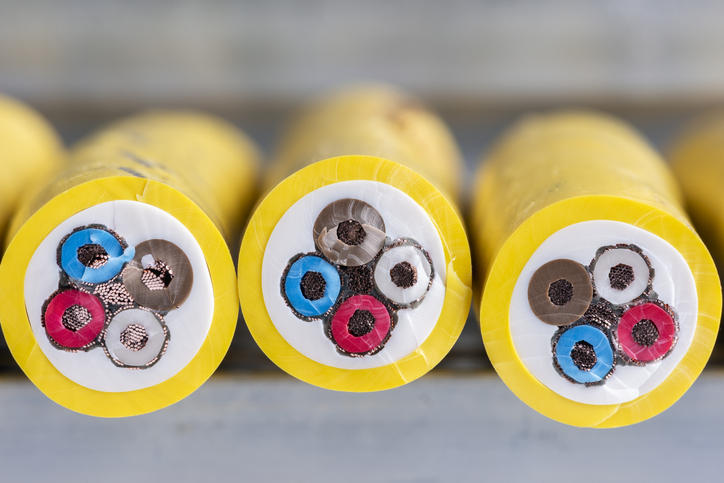

In wire and cable applications for high-temperature environments, mica provides essential fire resistance. Electrolock’s Pyrodox® mica-based insulation is specifically engineered for applications where fire survival matters most.

Critical Safety Layers in Battery Systems

As battery energy densities increase, the consequences of thermal runaway events become more severe. Mica sheet insulation plays an increasingly important role in battery safety systems designed to prevent or contain these events. Engineers incorporate mica-based materials as cell-to-cell insulation barriers that provide both electrical isolation and thermal resistance, thermal runaway mitigation layers that slow heat propagation between cells, and custom insulating sleeves and barriers tailored to specific cell geometries and battery pack configurations.

The low thermal conductivity of mica sheet insulation helps contain heat within individual cells during thermal events, buying precious time for battery management systems to respond and for occupants to evacuate safely.

Custom Engineering and Validated Performance

One of the mica sheet insulation’s greatest advantages is its versatility in manufacturing. The material can be cut, formed, laminated, molded, or precision-machined to meet nearly any specification. Electrolock works with customers to produce custom-engineered insulation components, including precision-cut spacers, washers, and gaskets for specific assembly requirements, application-specific insulating plates with complex geometries, and custom composite laminates that combine mica with other materials for optimized performance.

This customization capability extends beyond simple fabrication. Electrolock’s in-house testing services validate that mica-based insulation will perform as specified under actual operating conditions. Dielectric strength testing confirms voltage withstand capability, thermal cycling verifies dimensional stability across temperature ranges, and mechanical testing ensures durability during assembly and operation. This validated approach reduces field failures and gives engineers confidence that materials will perform as designed.

Electrolock: Engineering Mica Solutions Since 1957

Electrolock has been engineering mica-based insulation solutions for nearly seven decades. Our expertise spans the full range of mica applications — from ground wall tapes for multi-megawatt generators to thermal barriers for battery packs. We understand that mica sheet insulation is rarely a drop-in solution; optimal performance requires matching material properties, thickness, backing materials, and resin systems to specific application requirements.

Our engineering team works directly with customers to analyze operating conditions, define performance requirements, and develop solutions that balance electrical performance, thermal management, mechanical durability, and manufacturing considerations. Whether you need standard mica products or completely custom configurations, we bring both material expertise and manufacturing capabilities to deliver solutions that work.

Connect with Electrolock today to discuss your project needs, learn more about our testing services, or request a free sample of mica sheet insulation for your application.