Why EV Motors Demand Custom Insulation Solutions for Maximum Performance

Electric vehicle motors operate under demanding conditions that make custom motor slot insulation solutions the industry standard rather than a premium option. Unlike industrial motors, where standard solutions might suffice, EV applications require precisely engineered insulation that maximizes power density while meeting stringent automotive performance and durability requirements.

Below, we explore the reasons why motor slot insulation for EVs demands a customized approach, and how Electrolock is positioned to deliver the engineered solutions this space demands.

Custom Solutions for Your EV Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

EV Motor Slot Insulation Challenges Drive Custom Solutions

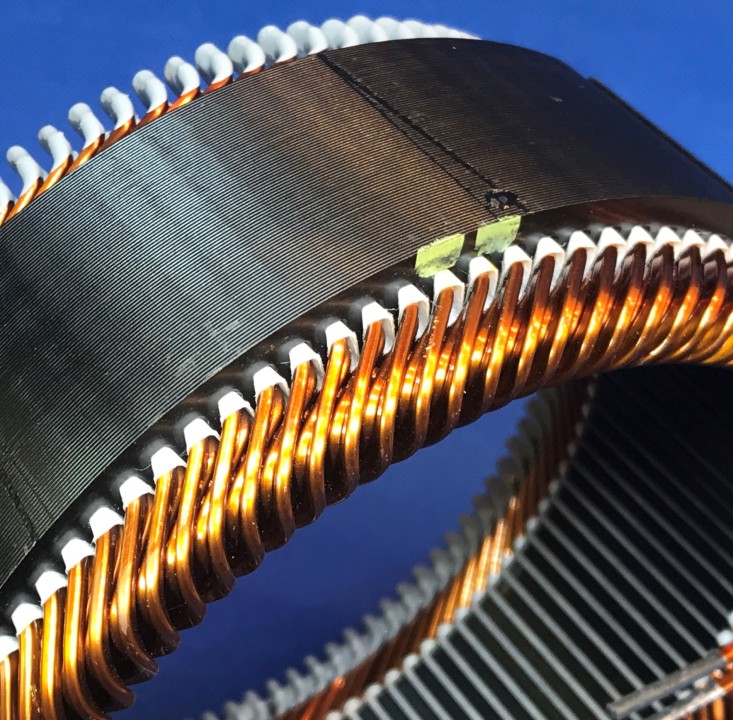

EV motors face unique challenges that standard insulation solutions simply cannot address effectively. Space optimization is critical — thinner insulation allows for more copper conductor in the slot, directly translating to higher power output. This space-performance relationship is fundamental to EV motor design, where every millimeter of saved insulation thickness can significantly impact motor power density.

Thermal management presents another significant challenge. EV motors run hot due to their compact, high-performance nature. While thermally conductive insulation materials would help motors operate more efficiently, current material technology limits these options. The industry continues to push for the thinnest possible insulation that can still maintain thermal performance requirements.

Chemical compatibility adds complexity that industrial motors rarely encounter. EV slot insulation must withstand exposure to automotive transmission fluids (ATFs) and other automotive chemicals throughout the motor’s operational life. This compatibility requirement extends to adhesive systems, which must maintain their bonding properties when exposed to these automotive fluids.

Long-term durability requirements are particularly stringent for EV applications. Motors must perform reliably for a decade or more, making material selection and construction design critical for sustained performance under automotive conditions. After all, the insulation solution should match the expected life of the motor itself.

Custom Material Construction Optimization for EV Performance

Achieving optimal EV motor slot insulation requires sophisticated multi-layer laminate constructions that balance multiple competing performance requirements. Engineers must optimize these constructions to simultaneously address thermal conductivity, dielectric strength, mechanical properties, and chemical compatibility within the thinnest possible profile.

The construction process involves going as thin as possible from a thickness perspective while still meeting all electrical and mechanical specifications. This optimization challenge requires careful material selection and layering strategies to ensure the final construction maintains dielectric breakdown resistance and partial discharge performance.

Advanced laminate designs enable manufacturers to fine-tune properties for specific EV applications. By combining different materials in precise configurations, engineers can create slot insulation that maximizes copper fill factor while maintaining all required performance characteristics. This level of customization is essential because each EV motor design presents unique space constraints and performance requirements.

EV-Specific Performance Requirements

EV motor slot insulation must meet several critical performance criteria that distinguish it from industrial motor applications. Dielectric breakdown and partial discharge resistance are fundamental electrical requirements that ensure safe operation under high-voltage conditions typical in EV motors.

Mechanical properties play an equally important role. Abrasion resistance and cut-through protection are essential during motor manufacturing and throughout the motor’s operational life. The insulation must withstand mechanical stresses during installation while maintaining its protective properties over time.

Chemical compatibility testing validates the insulation’s ability to resist degradation when exposed to automotive fluids. This testing encompasses both the insulation materials and adhesive systems, ensuring comprehensive compatibility with the automotive operating environment.

Thermal cycling durability testing simulates the repeated heating and cooling cycles that EV motors experience during normal operation. The insulation must maintain its electrical and mechanical properties through these thermal stresses to ensure long-term reliability.

The Future of EV Motor Slot Insulation

The automotive industry’s push for higher performance and greater efficiency continues to drive innovation in slot insulation materials and constructions. Emerging materials promise even thinner profiles while maintaining or improving performance characteristics.

Thermal conductivity improvements represent a significant development opportunity. If materials technology can deliver thermally conductive insulation at viable thicknesses, EV motors could achieve better thermal management while maintaining the space optimization benefits of thin insulation profiles.

Custom Solutions: The EV Standard

For EV motor manufacturers, custom motor slot insulation represents the standard approach rather than a specialty option. The unique combination of space constraints, thermal management requirements, chemical compatibility needs, and long-term durability demands makes off-the-shelf solutions inadequate for most EV applications.

At Electrolock, we have decades of experience working through these challenges. Our in-house testing and engineering teams give you the insight and data to find perfect-fit solutions — no matter the constraints of performance and design.

Contact Electrolock today to discuss how our custom slot insulation solutions can optimize your EV motor designs for maximum performance and reliability.