Optimizing Insulation Solutions for Medium and High-Voltage Motor Performance

Medium and high-voltage motor applications demand precise insulation solutions that balance electrical protection, thermal management, and mechanical durability. When evaluating insulation sleeving versus spiral wound tubing for motor systems, procurement professionals must consider how each solution addresses the unique challenges of stator windings, lead connections, and crossover insulation. Understanding these performance differences ensures optimal motor reliability while meeting evolving industry efficiency standards.

Custom Solutions for Your Specific Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

Motor Insulation Requirements Drive Material Selection

Modern motor coil insulation systems must simultaneously provide dielectric protection, manage thermal loads, and maintain mechanical integrity under demanding operational conditions. In medium and high-voltage applications, these requirements intensify significantly, particularly as industry trends toward more compact motor designs and stricter efficiency regulations under standards like IEEE 112-2017 continue driving innovation.

The selection between insulation sleeving and spiral wound solutions depends largely on specific motor components and their operational demands within the complete insulation system.

Understanding Solution Differences in Motor Context

Insulation Sleeving in Motor Applications

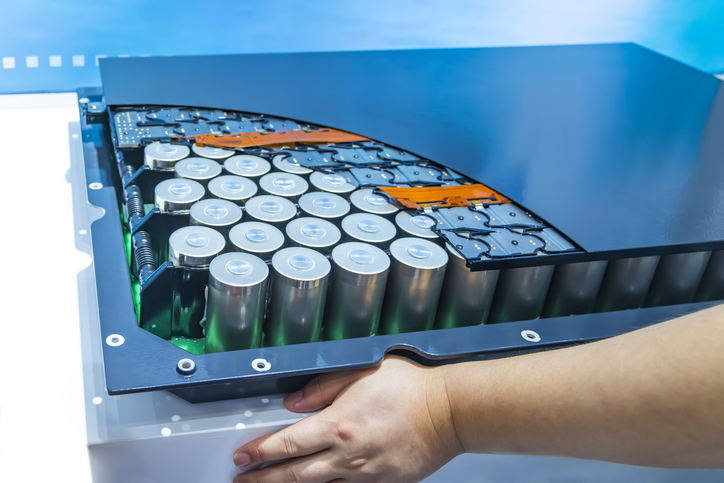

Traditional insulation sleeving, while effective in battery applications, faces limitations when adapted for motor environments. These solutions typically provide basic dielectric protection around individual conductors but lack the comprehensive performance characteristics required for demanding motor applications.

Standard sleeving approaches work adequately for lower-stress applications but may not address the complex thermal cycling, mechanical vibration, and electrical stress concentrations common in medium and high-voltage motor systems.

Spiral Wound Tubing for Motor Performance

Spiral wound tubing construction offers distinct advantages in motor applications through its multi-layer design approach. This construction method enables the integration of specialized materials — such as mica papers, aramid reinforcements, and polyester films — within a single protective structure tailored specifically for motor operating conditions.

The overlapping spiral construction provides enhanced mechanical durability against the vibration and thermal cycling inherent in motor operations, while enabling precise customization of electrical and thermal properties.

Component-Specific Performance Analysis

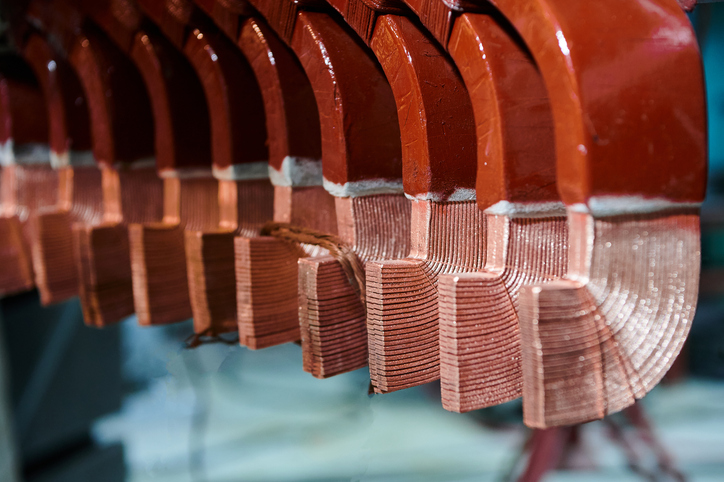

Stator Winding Protection

In form-wound stator coil applications, spiral-wound solutions demonstrate clear advantages. The ability to incorporate mica-based materials within the spiral construction provides the high-temperature stability and partial discharge resistance essential for reliable stator performance.

Spiral wound tubing can accommodate the precise wall thickness requirements needed to optimize copper fill factors while maintaining required dielectric strength — a critical consideration for maximizing power output in space-constrained motor designs.

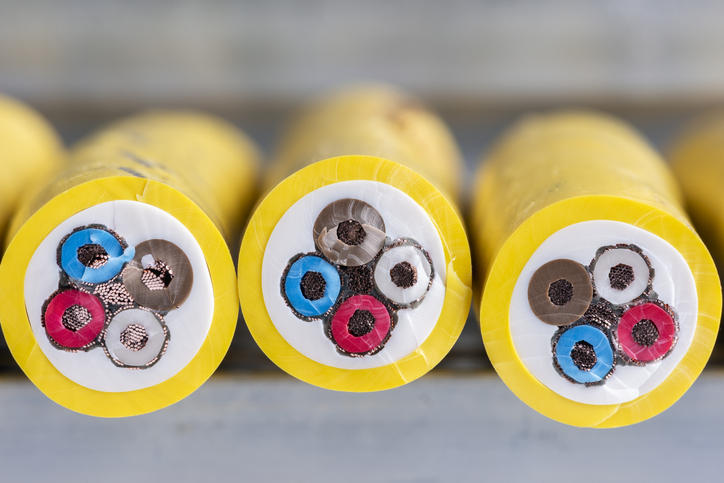

Lead Connection Insulation

Motor lead connections experience unique stress concentrations where conductors transition between different voltage potentials. Spiral wound tubing’s customizable construction enables the integration of gradient control materials and enhanced mechanical protection specifically designed for these critical transition zones.

The multi-layer approach allows for tailored electrical stress distribution, reducing the risk of premature failure at connection points where standard sleeving solutions may prove inadequate.

Crossover Insulation Requirements

In multi-turn motor configurations, crossover regions demand specialized protection against both electrical and mechanical stress. Spiral wound solutions excel here through their ability to maintain insulation integrity in geometrically complex areas while providing the mechanical support necessary during thermal cycling operations.

The engineered construction enables consistent performance across varying conductor positions and orientations — a significant advantage over conventional sleeving approaches that may not conform reliably to complex geometries.

Thermal and Electrical Performance in Motor Environments

Managing Motor Operating Temperatures

Motor applications typically operate at higher continuous temperatures than many other electrical systems. Advanced motor coil insulation requires materials capable of sustained performance at elevated temperatures while maintaining dimensional stability.

Spiral wound construction enables the selection and positioning of temperature-resistant materials like polyimide or aramid papers in critical thermal zones, while incorporating thermal management features that standard sleeving cannot provide.

Electrical Stress Distribution

High-voltage motor applications create significant electrical stress concentrations, particularly at insulation terminations and geometric discontinuities. Spiral wound tubing’s layered construction allows for engineered stress control through the strategic placement of semi-conductive materials and gradient control elements.

This engineered approach to stress management proves particularly valuable in applications operating above NEMA MG-1 standards, where conventional insulation approaches may not provide adequate protection against partial discharge activity.

Manufacturing and Maintenance Considerations

New Motor Manufacturing

In original equipment manufacturing, spiral wound tubing integrates effectively with automated coil forming processes. The customizable nature enables manufacturers to specify precise dimensional and performance characteristics that optimize both manufacturing efficiency and long-term reliability.

The ability to incorporate multiple functional materials within a single component reduces inventory complexity while ensuring consistent quality across production runs.

Motor Rewinding and Repair Applications

Motor rewinding scenarios often require insulation replacement in existing motor geometries where space constraints limit material options. Spiral wound solutions provide the flexibility needed to match original specifications while potentially upgrading performance characteristics.

The engineered construction approach enables repair technicians to address specific failure modes — such as inadequate thermal management or insufficient electrical protection — through targeted material selection within the spiral wound structure.

Selecting the Right Insulation Sleeving Solution for Motors

When evaluating these options for motor applications, several factors guide optimal selection:

Consider spiral wound tubing when:

- Applications involve medium to high-voltage motor systems

- Thermal management requirements exceed standard capabilities

- Complex geometries demand engineered stress control

- Long-term reliability in demanding environments justifies investment

- Customization needs require multiple material properties

Standard sleeving may suffice when:

- Systems require lower voltage applications with minimal thermal stress

- Budget constraints prioritize basic protection over enhanced performance

- Simple geometries don’t require specialized engineering

However, in most medium and high-voltage motor applications, spiral wound solutions provide the comprehensive protection and performance optimization that motor reliability demands.

Electrolock’s Engineering Expertise Drives Optimal Results

Every motor application presents unique requirements that standard catalog solutions may not address effectively. Electrolock’s comprehensive engineering capabilities include detailed application analysis, custom material selection, and validation testing to ensure optimal performance under specific operating conditions.

Our experience with motor and generator insulation systems enables informed guidance through the selection process, whether for new manufacturing or rewinding applications requiring upgraded performance.

Contact Electrolock today to discuss how our engineered insulation solutions can enhance the reliability and performance of your motor applications.