Engineering Excellence That Withstands the Extreme

Designing cables that can withstand extreme temperatures and maintain circuit integrity is a critical challenge for engineers working at the frontiers of technology. Traditional extruded plastics or rubber insulation often fail catastrophically when exposed to high heat, fire, or mechanical stress, leaving critical systems vulnerable at precisely the moment they’re needed most. For applications requiring insulation at temperatures up to 1000℃, a more robust solution is necessary. Premium mica cable tape offers a proven way to meet these demanding requirements, delivering superior thermal performance, fire resistance, and long-term reliability that engineers can trust.

Custom Solutions for Your Specific Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

The Critical Challenges of High-Temperature Cable Design

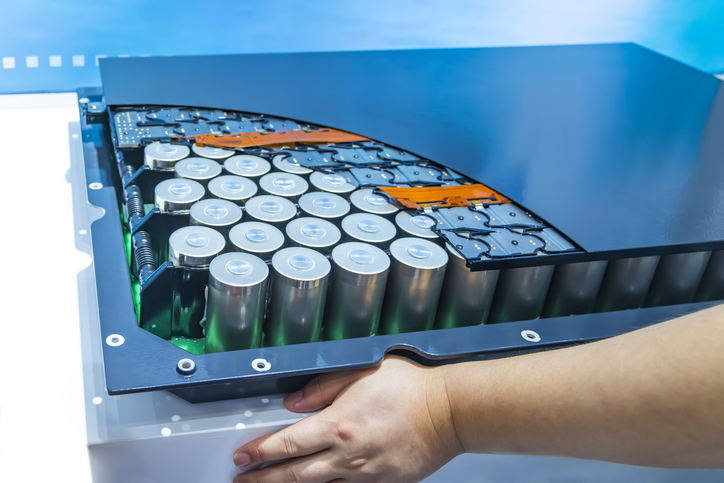

High-temperature cable applications span a wide range of industries where failure is not an option — from appliance manufacturing and industrial furnaces to aerospace and military shipboard systems. In these unforgiving environments, conventional insulation materials quickly reach their thermal limits, risking circuit failure or degradation that can compromise entire operations. Engineers also face increasingly stringent fire safety requirements, including low smoke and halogen-free standards, especially in enclosed or critical environments where every second of circuit integrity matters. Maintaining reliable performance under these extreme conditions — often for extended periods — is essential for safety, compliance, and operational continuity.

How Premium Mica Cable Tape Solves These Mission-Critical Challenges

Premium mica cable tape provides a unique combination of heat resistance and mechanical stability that other materials simply cannot match. Since 1957, Electrolock has been engineering solutions that build success from the inside out, and our Pyrodox® line of mica tapes exemplifies this commitment to excellence.

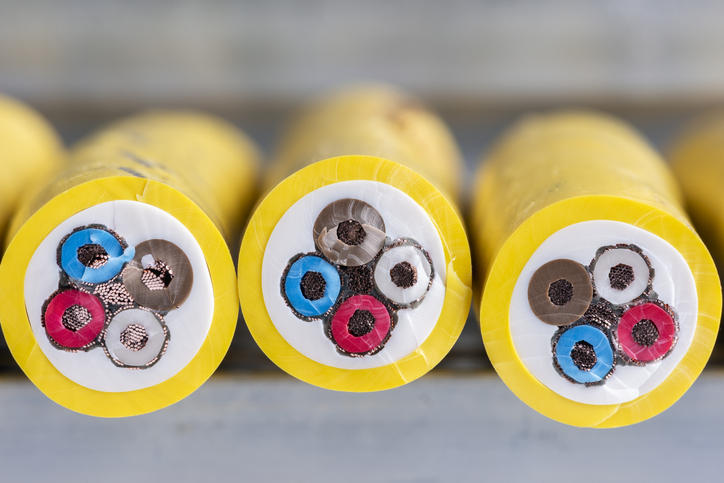

These advanced materials feature thin inorganic mica paper bonded with high-temperature silicone resins to a reinforcing backing (typically glass). This design allows the tape to be precision-slit to widths of less than 0.1 inches and spiral-wrapped around wires as small as 22 gauge, delivering uniform insulation even on fine-gauge conductors where precision matters most.

Pyrodox mica tapes have been widely adopted in applications requiring UL-certified high-temperature performance that engineers depend on. They are successfully used in UL 5107, UL 5128, and UL 2196 cables for furnaces, thermocouples, appliance wiring, and igniter cables. In military shipboard applications, Pyrodox provides low-smoke, halogen-free insulation that maintains circuit integrity under fire and heat stress when lives could be on the line. The tape’s inorganic mica composition ensures it does not burn, degrade, or release toxic fumes, offering unmatched fire survival capabilities that provide critical evacuation time.

Engineered Variants and Manufacturing Advantages That Drive Efficiency

The Pyrodox family includes several styles, each precisely tailored to specific application requirements. These different offerings vary in thickness, mica content, and weight, allowing engineers to select exactly the right tape for their temperature, voltage, and mechanical specifications. One specialized variant, Pyrodox GX, uses premium mica with a halogen-free silicone binder and non-alkaline fiberglass backing. Pyrodox GX is engineered to endure extreme electrical and thermal overloads while tolerating high-moisture environments, making it ideal for cables requiring extended fire survival time. And due to its premium mica composition, it performs alternatives that rely on standard phlogopite and muscovite micas.

Pyrodox tapes are supplied in slit pads or traverse-wound spools, offering long continuous lengths without bulky tape splices that can compromise performance. This thoughtful design minimizes taping machine downtime and ensures consistent wall thickness along the cable, helping manufacturers maintain high-quality production standards while reducing operational inefficiencies that impact the bottom line.

Industry Validation and Proven Reliability Where It Matters Most

Lay flat tubing excels in automated manufacturing environments. The flattened storage configuration reduces shipping costs and simplifies handling systems. When expanded during installation, the tubing provides complete encapsulation with minimal operator intervention. This characteristic makes lay-flat solutions particularly attractive for high-volume production scenarios where labor efficiency impacts overall costs.

Spiral wound tubing requires more consideration during installation planning. However, this investment in setup complexity pays dividends through enhanced customization options. Electrolock’s spiral wound solutions can be supplied with specialized features, including notched cuts, sealed end caps, and custom dimensions that integrate seamlessly into specific manufacturing processes.

Customization Capabilities and Industrial Insulation Solutions

Pyrodox mica cable tapes have earned a reputation for unwavering reliability and performance across multiple industries where failure is not acceptable. Notably, Pyrodox is the only tape that consistently passes UL 2196 testing requirements for fire survival cables, providing engineers with the confidence they need in their protective capabilities. From oil exploration’s harsh downhole conditions and aerospace’s thermal extremes to defense applications, mass transit systems, and high-temperature industrial processes, Pyrodox delivers proven circuit integrity and thermal protection precisely where it matters most.

Building Success from the Inside Out With Electrolock

For engineers and cable manufacturers facing extreme thermal, mechanical, and fire-resistant requirements, mica cable tape represents more than just a component — it’s a critical solution that enables innovation in the most demanding applications. Electrolock’s Pyrodox line offers unmatched high-temperature performance, manufacturing efficiency, and reliability forged through decades of materials engineering expertise, ensuring that cables maintain circuit integrity even in the most unforgiving environments.

By selecting the right Pyrodox variant for their specific application, engineers can achieve long-term durability, UL compliance, and the peace of mind that comes from partnering with a company that has been building success from the inside out since 1957.

Contact Electrolock today to discuss how our premium mica cable tape solutions can enhance the reliability of your high-temperature cable applications.