Evaluating Material Options for EV Battery Safety and Performance

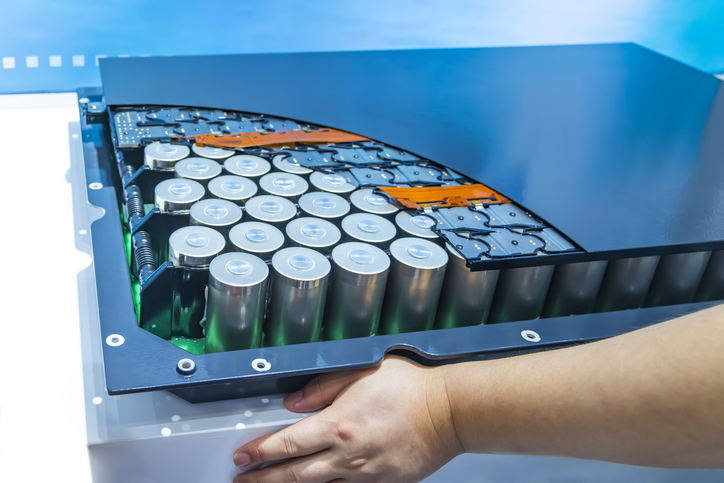

As electric vehicle adoption accelerates, ensuring robust thermal propagation protection in EV battery systems has become increasingly critical. When thermal runaway occurs — a rapid, uncontrollable temperature increase in battery cells — effective thermal propagation protection solutions can provide crucial evacuation time and prevent catastrophic cell-to-cell failure propagation. Understanding the performance characteristics of different protection materials helps procurement teams make informed decisions for their specific EV battery applications.

Custom Solutions for Your Specific Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

Understanding Thermal Runaway and Protection Requirements

Thermal runaway represents a significant safety challenge in lithium-ion battery systems, where individual cell failures can cascade throughout entire battery packs. While Electrolock’s solutions focus on mitigating thermal runaway impact and providing critical evacuation time rather than preventing its initial occurrence, the selection of appropriate thermal propagation protection materials directly influences overall system safety.

Current safety regulations, including UN GTR No. 20 and the NHTSA’s Battery Safety Initiative, establish minimum requirements for thermal propagation protection, typically mandating a period of safe evacuation time when thermal events occur.

Three Primary Material Approaches for EV Battery Protection

Mica-Based Thermal Barriers

Mica remains the industry standard for high-performance thermal propagation protection in EV applications. Its natural crystalline structure provides exceptional thermal stability and flame resistance capabilities that prove essential when battery temperatures exceed critical thresholds.

Performance Characteristics:

- Exceptional high-temperature stability, maintaining integrity at extreme temperatures

- Superior flame retardancy with UL 94 V-0 rating

- Low thermal conductivity prevents heat transfer between cells

- Excellent dielectric properties provide electrical isolation

- Design flexibility available in rigid, flexible, and tape configurations

Application Diversity: Mica-based solutions excel across multiple battery pack protection levels, from cell-to-cell barriers to module-level insulation and pack perimeter protection. The material’s adaptability enables engineers to implement comprehensive thermal management strategies throughout battery assemblies.

Cost Considerations: Among thermal runaway barrier materials, mica offers the most cost-effective solution while maintaining superior performance characteristics, making it particularly attractive for large-scale EV production applications.

Ceramic Insulation Solutions

Ceramic materials provide exceptional performance in extreme temperature environments where maximum thermal protection is required. These solutions excel in high-stress applications where preventing thermal runaway propagation is paramount.

Performance Characteristics:

- Outstanding thermal shock resistance under rapid temperature changes

- Exceptional dimensional stability, maintaining protective geometry during thermal events

- Superior chemical resistance against battery electrolytes and decomposition products

- High mechanical strength withstands physical stresses during battery operation

Application Diversity: Ceramic solutions prove particularly valuable in commercial EV applications and high-performance battery systems where enhanced protection justifies additional material investment. These materials work effectively in both rigid barrier applications and specialized thermal management configurations.

Cost Considerations: While ceramic materials require a higher initial investment compared to other options, their exceptional durability and protection capabilities often justify the cost in mission-critical applications where battery failure consequences are severe.

PET-Based Protection Systems

PET insulation materials offer balanced performance for EV applications requiring reliable thermal protection with manufacturing efficiency considerations. These solutions provide effective thermal propagation barriers while maintaining compatibility with automated production processes.

Performance Characteristics:

- Good thermal resistance suitable for moderate temperature applications

- Excellent mechanical durability, resisting manufacturing and handling stresses

- Chemical compatibility with battery components and assembly processes

- Lightweight characteristics supporting overall vehicle efficiency goals

Application Diversity: PET solutions work effectively in passenger EV applications where standard thermal protection requirements align with material capabilities. These materials integrate well with multi-layered insulation systems and can be combined with other materials for enhanced protection.

Cost Considerations: PET-based solutions typically offer the most economical option for applications where moderate thermal protection meets safety requirements, making them attractive for high-volume consumer EV production.

Multi-Layered System Approaches

Beyond individual material solutions, multi-layered thermal insulation systems combine different materials to achieve optimized performance across various protection levels. These engineered systems enable customized thermal management strategies addressing specific battery pack configurations and performance requirements.

Multi-layered approaches typically integrate primary thermal barriers with secondary protection elements, creating redundant safety systems that maintain protection even when individual components experience degradation during thermal events.

Protection Implementation Across Battery Levels

Cell-to-Cell Protection

Individual cell protection requires materials capable of containing thermal events at the source while maintaining compact dimensions. Solutions must balance thermal protection with space efficiency to maximize battery energy density.

Module-Level Barriers

Module-level protection focuses on preventing thermal propagation between battery modules while accommodating various module configurations and cooling system requirements. Materials must provide reliable performance across different module designs and sizes.

Pack-Level Insulation

Pack-level protection systems, including Electrolock’s Go-Therm Thermal Runaway Barrier, provide comprehensive thermal management for complete battery assemblies. These solutions focus on occupant protection and system-level thermal control.

Engineering the Right Thermal Propagation Protection Solution

Selecting optimal thermal propagation protection requires careful evaluation of multiple factors, including battery chemistry compatibility, thermal performance requirements, manufacturing constraints, and long-term reliability needs. Each EV application presents unique challenges requiring customized material selection and system design.

Electrolock’s comprehensive thermal insulation expertise enables detailed application analysis and custom solution development tailored to specific EV battery requirements. Our engineering approach considers both standard and custom configurations to optimize thermal protection while meeting manufacturing and cost objectives.

Working with experienced thermal insulation specialists ensures that protection solutions address both immediate safety requirements and long-term performance demands across various EV operating conditions.

Contact Electrolock today to discuss how our thermal propagation protection solutions can enhance the safety and reliability of your EV battery systems.