Commonly used in wires, cables, and batteries, a dielectric barrier prevent electrical discharge between two electrodes. They are primarily used to discourage thermal runaway and overheating in their applications and are crucial to maintaining the safety and functionality of the product.

Materials Used as Dielectric Barriers

Mica

Mica is a very poor conductor of electricity, and with a dielectric strength of 2000 volts per millimeter, it is very good at withstanding high voltages. It forms in thin sheets, making it lightweight, flexible, durable, and easy to cut to size. This material is also able to withstand extremely high temperatures, so it will not melt or break down if exposed to a wire or battery that is overheating.

Polyimide

Polyimide is a popular dielectric material due to its thermal stability, impressive mechanical properties, and high electrical insulation properties. Generally, it is used to keep electronic wires from igniting or succumbing to low or high temperatures. It can also be reinforced with fiberglass to make it more rigid, depending on the application.

Teflon® (PTFE)

Teflon, or PTFE, is a chemically resistant polymer that can tolerate an extremely wide range of temperatures—from -400℉ to 500℉. Its high dielectric strength makes it a good insulator for batteries or wires and cables, and it is extremely durable.

PET

PET is a high-strength polymer with low moisture absorption. It has good dielectric properties, not allowing electric current to pass through it, making it a great choice for wire coatings, battery cell wrappers, and other dielectric barrier applications.

Polypropylene

This flexible polymer is resistant to chemicals and heat and has impressive impact tolerance. Polypropylene does not conduct electricity well, and since it can also handle high temperatures, it is a common choice for dielectric barriers.

Fiberglass

Fiberglass is non-corrosive, heat resistant, and durable. It can maintain its structure under mechanical stress and extreme temperatures. Fiberglass is also non-conductive, making it a good choice for insulation applications as well as dielectric barriers.

Applications of Dielectric Barriers

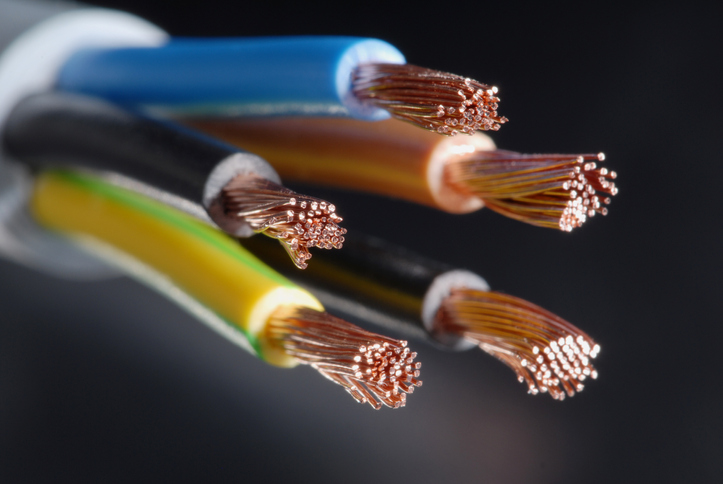

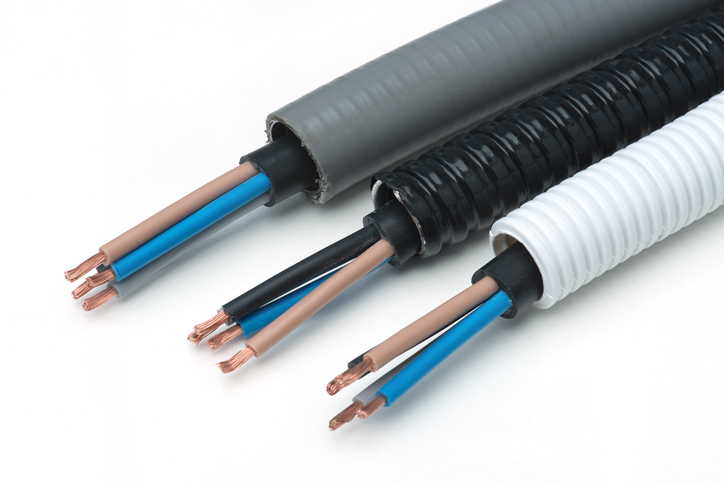

Wire and Cable Insulating Tapes

Insulating tapes for wires and cables are generally made from mica, polyimide, or Teflon/PTFE. Primarily, these tapes are used for fire survival for control and power cables, mass transit, aircraft, oil wells, thermocouples, appliance wires, and shipboard cables.

At Electrolock Inc., there are various insulation materials for wires and cables, including:

- Polyimide Products: Apical and Kapton tapes

- Teflon Products: FEP, PFA, PTFE, Sintered, Tensilized, UnSintered tapes

- Mica Products: Nomex® and Pyrodox products

Battery Insulation

Battery insulation is crucial to the health of the battery and the safety of those using it. These products are generally made from polyimide, PET, polypropylene, fiberglass, PTFE, and mica. Various products can be chosen based on the type of battery, the battery’s application, and cost. Regardless, all of these products can prevent thermal runaway and overheating from cell to cell or for individual cells.

There are numerous battery-insulating products available at Electrolock Inc. From cell wrappers to heat shrink spiral wound tubing, we have it all:

- Polyimide Products: Cell Wrappers, Jelly Roll Wrap, and Polyimide Laminates

- PET Products: Cell Wrappers, Die Cut Top & Bottom Cell Insulator, Jelly Roll Wrap, and PET Layflat Tubes

- Polypropylene Products: Cell Wrappers and Jelly Roll Wrap

- Fiberglass Products: CraneGlas®, Die Cut Top & Bottom Cell Insulator, Go-Therm Thermal Runaway Barrier, and Pyrodox with fiberglass backing,

- PTFE Products: Die Cut Top & Bottom Cell Insulator

- Mica Products: Pyrel-Therm and Pyrodox

Turn to Electrolock For All of Your Dielectric Barrier Needs

Preventing overheating, thermal runaway, and potential electric shock is critical in all applications. Whether it is in batteries or wire and cable applications, having the proper dielectric barriers is paramount.

At Electrolock Inc. we understand the importance of implementing the right type of insulation and we will work with you to understand your application and find the right product for you. Our team can also perform analytical and high-voltage testing on insulation materials so we can be sure the product chosen is right for you. If you can’t find exactly what you need, we offer custom solution design to develop an entirely new product that will meet every one of your needs.

Contact our team to find the right solution for your application.