Die cutting is a manufacturing process that utilizes a machine and a metal component called a die to cut specific shapes from a sheet of material. It is a quick and easy way to create customized materials for specific applications. Working with a manufacturer who provides die-cut solutions for electrical insulation and cell wrapping allows their customers to customize their products to perfectly fit the application.

How Does Die Cutting Work?

The process of die-cutting is fairly straightforward. A metal die is created in the desired shape and is then pressed against a hardened anvil roll to cut the shape out of the material passing through the two components. This creates neat and precise outlines by cutting, forming, and shearing products from sheets or rolls of material.

The created die can also be reused, meaning the desired shape and product can be replicated as often as needed. Die-cutting is the best method for high-volume runs that require precision and accuracy.

Die-Cutting Creates Custom Electrical Insulation and Cell Wrapping Solutions

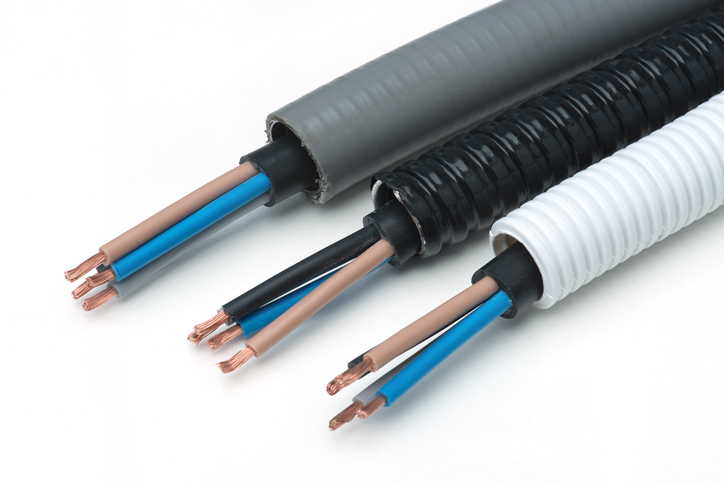

Die-cutting creates custom insulation solutions by puncturing electrical insulation materials and cell wrapping. Materials such as mica tape, wire and cable insulation tape, silica tape, and cell wrappers made of polyimide, PET, and polypropylene are just some of the insulation options that can undergo die-cutting.

Advantages of Die-Cut Solutions for Electrical Insulation and Cell Wrapping

There are various benefits to choosing die-cut solutions rather than stock materials. From having a customized product you know will fit to reducing waste, die-cut solutions are worth considering.

Uniformity and Customization

Many complex shapes are found in electrical applications, especially in battery insulation. Die-cutting electrical insulation materials create the exact shape and size needed for the application while also being able to maintain uniformity throughout production. This means all of your products will have the same dimensions and look the exact same throughout the entirety of their manufacturing.

Reproducibility

The dies used in this manufacturing process can be used repeatedly. So, no matter how many products you need or how many rounds of manufacturing you need to do, your die will still be able to reproduce the same product.

Reduced Waste

When using die-cutting to produce customized electrical insulation and cell wrappers, there is very little waste produced. Creating custom products for specific applications means they will fit without needing to be altered, producing less waste than if you were to use a stock product. Additionally, the actual process of die-cutting doesn’t produce much waste. Since the die can be reused and there is very little product left over, excess material or wasted dies are rare.

Easily Tackle Complex Designs

Rather than having to hand cut your electrical insulation or cell wrapping, dies can be created in nearly any shape, meaning even your most complex designs can be created through die-cutting. This will save you time and money in the long run and make it easier to produce these complex products repeatedly.

Trust Electrolock with Your Die-Cut Solutions for Electrical Insulation and Cell Wrapping

Not only does Electrolock have all of the materials and products you could possibly need for your electrical insulation projects, but we also offer various services to ensure your product is the best possible fit for your needs. Whether you need analytical and high-voltage testing, custom solution designs, or manufacturing services, we have you covered.

When you work with Electrolock, you access our leading-edge technology to identify, examine, evaluate, and compare your insulation materials. Our team can even help you develop more efficient designs with our high-voltage lab and solution design services. And if you need a customized design, our manufacturing services can convert your materials however you need. From slitting and rewinding to punching and rotary die-cutting, Electrolock has all of the manufacturing capabilities to create bespoke insulation solutions.

Contact our team today to see what we can do for you.