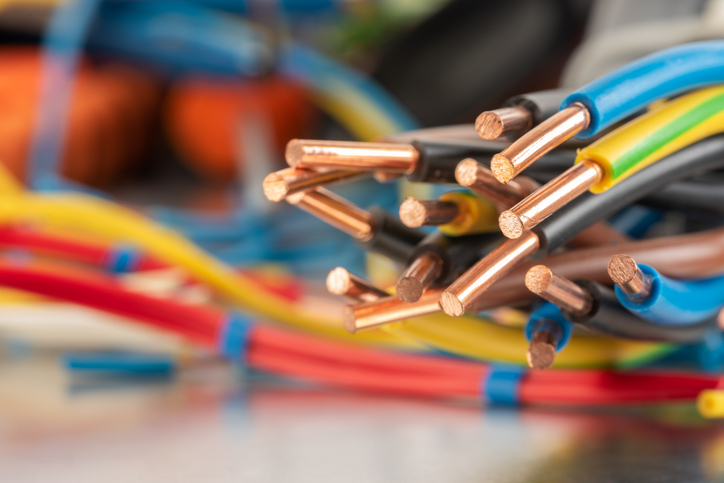

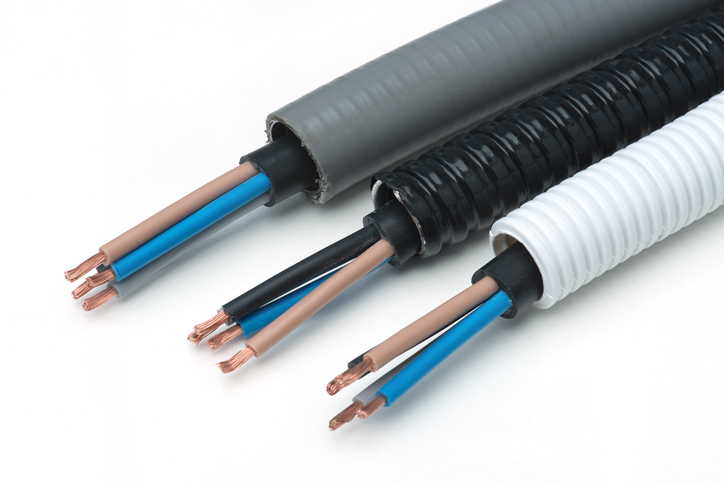

There are various types of electrical wire insulation on the market, with each implementing different materials including polyimide, Teflon®, and mica tapes. Each has properties that make them ideal for electrical insulation for specific applications — from aircraft to appliances. Today we’re exploring the properties of these different types of electrical wire insulation and their applications.

Properties of Different Types of Electrical Wire Insulation

The three main types of electrical wire insulation include polyimide, Teflon®, and mica tapes. Each of these options has unique properties that make them ideal for use in electrical applications.

Polyimide

Polyimide is chosen for electrical applications due to its many advantageous properties. With the ability to withstand temperatures greater than 400ºC, or 752ºF, chemical resistance, and mechanical durability, polyimide is a great choice for demanding electrical applications.

There are two primary polyimide tapes — Apical® and Kapton®. Apical® polyimide tape has excellent mechanical properties and chemical resistance. Similarly, Kapton® polyimide tape has good mechanical properties and chemical resistance while also being flexible.

Teflon®

As an electrical insulator, Teflon® is a great choice because it can withstand temperatures up to 260ºC, or 500ºF, has good dielectric properties, and is resistant to many chemicals. There are numerous options when it comes to Teflon® tapes, all of which have desirable properties that distinguish their applications:

- FEP is tough and flexible while exhibiting good chemical resistance.

- PFA is flexible with good dielectric strength. It is resistant to stress, chemicals, and fire, and can withstand both high and low temperatures.

- PTFE is the most popular form of Teflon® and is resistant to water, chemicals, and high and low temperatures.

- Sintered Teflon® exhibits high elongation and is resistant to weathering.

- Tensilized Teflon® has great tensile strength.

- UnSintered Teflon® exhibits excellent dielectric properties.

Mica

Mica tape is commonly used in electrical applications due to its water and chemical resistance. There are two primary types of mica tape — Nomex® and Pyrodox®. Nomex® has high dielectric strength and flexibility, is resilient, and is an excellent insulator. While there are numerous varieties of Pyrodox®, they all have similar characteristics in that they are heat-treated mica tapes capable of withstanding electrical and thermal overloads in environments with high moisture.

The different types of Pyrodox® include:

- Pyrodox® GP: a phlogopite mica tape made from silicone binder with a fiberglass backing

- Pyrodox® GM: a calcined muscovite mica tape

- Pyrodox® PEP: heat-treated phlogopite mica tape with a silicone binder and a polyethylene backing

- Pyrodox® SG: synthetic mica tape with a silicone binder and a fiberglass backing

- Pyrodox® SEP: another synthetic mica tape with a silicone binder and a polyethylene backing

- Pyrodox® PET: a phlogopite mica tape with a silicone binder and a polyester backing.

Applications of Each Type of Electrical Wire Insulation

Polyimide

Apical® polyimide tapes are used in many critical applications due to their ability to withstand extreme temperatures. You can find these tapes used in commercial and military aircraft, aerospace applications, satellites, and missiles.

Kapton® polyimide tapes can be used in many applications, including wire and cable tapes, formed coil insulation, capacitor and transformer insulation, and magnetic wire insulation.

Teflon®

Each type of Teflon® has its own applications due to its structure and properties. For electrical components for computers and aircraft, FEP Teflon® is the top choice. PFA Teflon® is used in wire constructions, heater cables, heavy wall conduits, cable jacketing, and more. For more critical applications, such as military, aerospace, coaxial, and appliance wiring applications, PTFE Teflon® is a common option. Sintered Teflon® is used as conductor insulation while UnSintered Teflon® is used in capacitors, special cables, and electrical instruments. Finally, Tensilized Teflon® is commonly found in separators, transformers, slot liners, and harness wrapping.

Mica

The two types of mica tape have different uses. Nomex® is used as motor phase insulation, transformer coil fillers, motor conductor wrap, coil wrap, and transformer ground insulation. Because Pyrodox® is resistant to flame, it is used in applications where fire survival is necessary, including power cables, mass transit, aircraft, oil wells, thermocouples, appliance wires, and shipboard cables.

Electrolock Carries All Types of Electrical Wire Insulation Options

For nearly 70 years, Electrolock has been engineering solutions for various industries, including wire and cable insulation. Our materials can be used for shielding or as flame barriers, dielectric barriers, and separators. We also have experience engineering high voltage insulation materials, battery insulation, spiral wound tubing, Porex tubing, thermal insulation, and polyshrink film.

If you are looking for electrical wire insulation, contact our team today. We can help you choose the right solution for you, or engineer something new to meet all your needs.