Polyshrink PVF

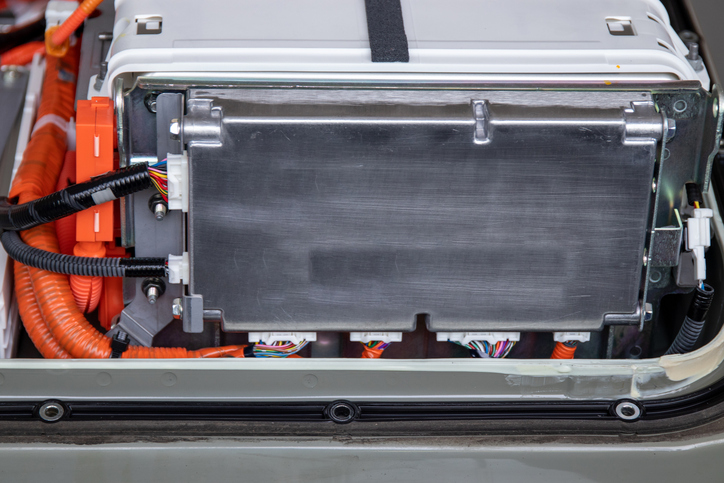

So much of what goes into the end result of a product stems from what happens during production. Testing, validating, and perfecting a process over time is something our engineers take with a hands-on approach. This is evident with our PVF shrink films, a tailored approach to high performance sacrifice and release films for high voltage coil production. It’s this intentional side of process development that we believe makes the difference to our customers.

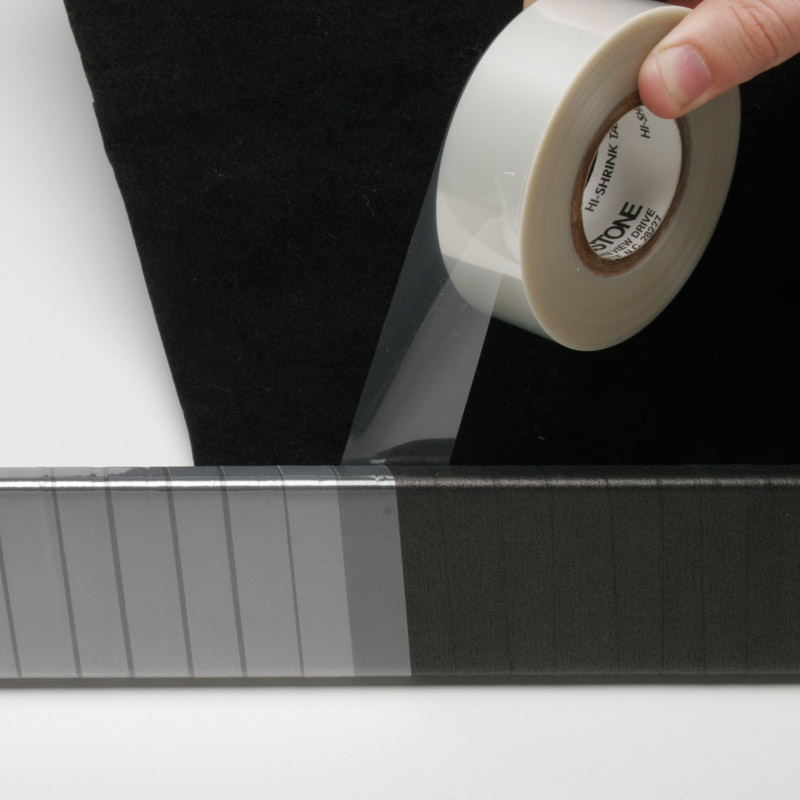

Process aids, such as specialty shrink films, make a monumental difference in the manufacturing of high voltage coils and composites. While there are many release coatings, Electrolock offers one that is unique: a non-dispersion, PVF film coating. This customized coating is applied to our heat shrinkable polyester film to create a smooth, easy release from the cured composite.

Practical Applications

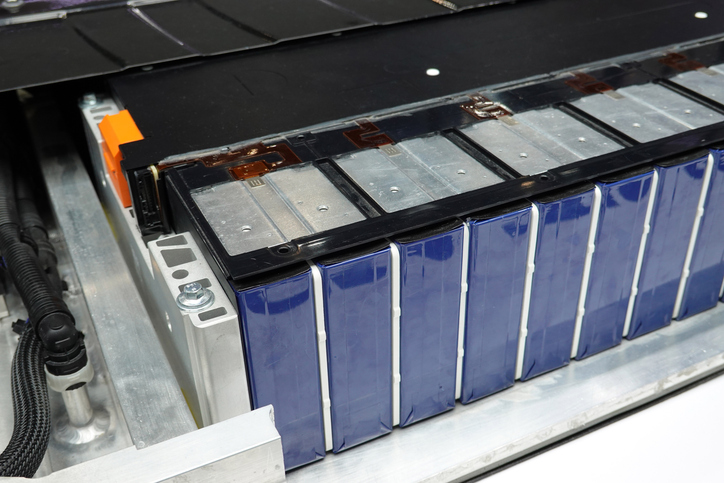

Polyshrink PVF-series shrink films combine the shrink properties of Electrolock’s standard Polyshrink tapes with the high-temperature release attribute of PVF. The compression force characteristic of our polyester-based films makes for an effective and useful tool for consolidating and compressing electrical coils. They are commonly used as a sacrifice layer to compact the pre-consolidated coil or the finished high voltage hot pressed coils, producing a consistent corner radius. These customizable shrink films are available in 2-mil thickness and slit to custom widths.

The advantage of PVF coating is a solid, high-temperature release film. The maximum temperature of our Polyshrink tapes is 160°C. Electrolock’s Polyshrink PVF release tape can accommodate up to 185°C. This higher temperature release is especially important in application that don’t have precise temperature control. The result is an even, clean release from epoxy composites even with extreme temperatures. It allows the tape to release in one continuous wrap. There is zero transfer of the release coating to the underlying composite part, leaving a clean, consistent surface finish.

Contact Electrolock today to learn more about Polyshrink PVF and to request a sample.