Exploring the Important Role of Heat-Resistant Electrical Tape

When temperatures exceed material limits in electrical systems, insulation breaks down, conductors short, and catastrophic failures occur. Heat-resistant electrical tape provides critical defense, but selecting appropriate solutions requires understanding material capabilities and application demands.

Below, we’ll take a look at material types and temperature coverage offered by heat-resistant electrical tapes, and how working with Electrolock can help you identify the best options for your unique application.

Custom Solutions for Your Specific Applications: Reach out to the Electrolock team today to begin discussing your next electrical insulation project.

Understanding Thermal Failure in Electrical Systems

Thermal failure occurs when insulation degrades under sustained or peak temperature exposure. As temperatures rise beyond design limits, polymeric materials soften, dielectric strength diminishes, and mechanical properties deteriorate. Short circuits develop between conductors, electrical arcing ignites surrounding materials, and in critical systems — think emergency circuits, aircraft harnesses, or battery connections — single failures can cascade into system loss.

Heat-resistant electrical tape maintains integrity across extended temperature ranges. A tape rated for 130°C proves inadequate for applications experiencing 300°C or flame exposure. Matching specifications to operating conditions ensures reliable performance.

Key Materials in Heat-Resistant Electrical Tape

Different types of electrical insulation materials deliver distinct thermal capabilities, each suited to specific application requirements.

Mica-Based Tapes

For extreme temperature and fire survival applications, mica-based tapes represent the premium solution. Electrolock’s proprietary Pyrodox® cable tapes combine thin mica paper with halogen-free silicone binders and reinforcing substrates to deliver:

- Continuous operation up to 500°C with peak resistance to 1800°F during fire exposure

- UL 94 V-0 flame rating for fire survival

- Excellent dielectric strength for high-voltage environments

These tapes prove essential for fire-rated circuit integrity cables where emergency systems must remain operational during fire events. Applications include mass transit, aircraft, oil well equipment, and critical infrastructure.

Polyimide Tapes

Polyimide-based tapes — such as brand names Kapton® and Apical® — deliver outstanding thermal stability for continuous high-temperature service. Withstanding temperatures exceeding 500°C (932°F), these high-temperature materials provide exceptional mechanical strength and chemical resistance. Aerospace, military, and satellite applications specify polyimide tapes for extreme environment reliability.

PTFE (Teflon®) Tapes

PTFE tapes offer excellent chemical resistance and dielectric properties alongside temperature capability up to 260°C (500°F). Available in multiple configurations — FEP, PFA, sintered, and unsintered — PTFE tapes deliver flexibility in matching application requirements with broad chemical compatibility.

Nomex® Aramid Tapes

Nomex® tapes combine good thermal resistance (up to 220°C) with exceptional mechanical strength and tear resistance. Their conformability makes them valuable for motor and generator applications requiring phase insulation, conductor wrap, and coil protection. The material withstands the stresses of coil forming and installation while maintaining thermal protection during operation.

Critical Applications for Heat-Resistant Electrical Tape

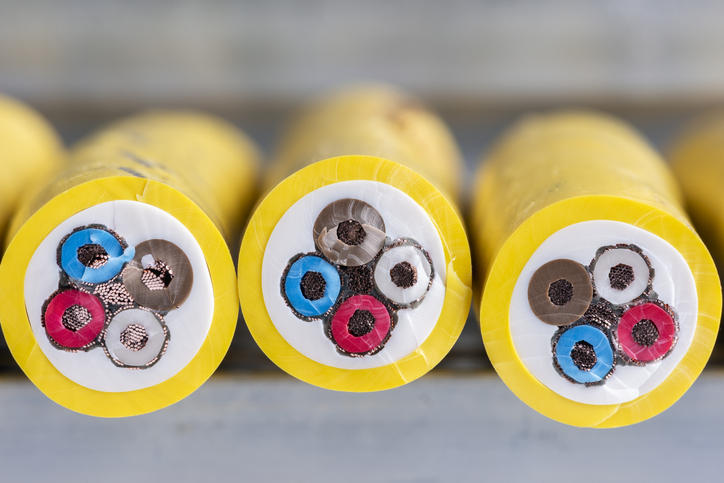

Wire and Cable Systems

High-temperature wire and cable applications demand insulation maintaining circuit integrity under extreme conditions. Fire survival cables must operate when exposed to flame. Downhole cables encounter sustained heat, mechanical stress, and chemical exposure. Aerospace harnesses face wide temperature swings and vibration.

Pyrodox® mica tapes meet UL 5107, UL 5128, and UL 2196 standards. These tapes can be precision-slit to widths less than 1/8 inch and supplied on traverse-wound spools for high-speed automated wrapping.

Motor and Generator Coils

Electrical machines generate significant heat during operation. Turn insulation, conductor wraps, and phase barriers must withstand thermal loads from electrical losses and potential fault conditions. Heat-resistant tapes protect critical coil regions, particularly crossover points and end windings, where mechanical stress combines with thermal exposure.

Battery Systems and High-Voltage Connections

Modern battery packs and high-voltage systems present unique insulation challenges. Busbar connections require materials combining dielectric strength with thermal resistance. Heat-resistant tapes, particularly mica-based solutions, deliver the electrical isolation and thermal capability required for safe operation.

Industrial Equipment

Manufacturing processes involving heat treat operations, furnaces, or high-temperature curing require harness protection that withstands sustained elevated temperatures. Heat-resistant tapes protect wiring and sensor connections where standard materials would fail within hours.

Selecting the Right Heat-Resistant Tape

Optimal tape selection requires evaluating multiple performance parameters:

Temperature Requirements: Distinguish between continuous operating temperature and peak exposure. A system operating at 200°C but spiking to 400°C during transients requires tape rated for peak exposure. Consider both maximum temperature and duration.

Electrical Requirements: Dielectric strength needs vary dramatically based on voltage levels. Medium and high-voltage applications demand materials with proven voltage endurance and partial discharge resistance. Lower-voltage applications may prioritize flexibility or adhesion.

Mechanical Demands: Application conditions determine required mechanical properties. Does the tape need to conform to irregular surfaces? Must it withstand abrasion during installation or service? Tapes wrapping moving components require different characteristics than those protecting stationary conductors.

Environmental Factors: Chemical exposure, moisture, UV radiation, and flame exposure all influence material selection. Testing and validation under conditions simulating service environments ensure selected tapes perform reliably throughout their service life.

Manufacturing Compatibility: Consider how tapes integrate with production processes. Can they be applied with existing equipment? Are special configurations, like traverse-wound spools or specific widths, required for automated processing? Manufacturing efficiency impacts total system cost significantly.

Engineer Thermal Protection Solutions With Electrolock

Since 1957, Electrolock has engineered insulation solutions for demanding thermal and electrical environments. Our approach extends beyond supplying products; we develop optimized solutions for specific application requirements.

Our Pyrodox® cable tape line offers configurations engineered for distinct applications. Tapes are available in thicknesses less than 0.003 inches, precision-slit to exact specifications, and supplied in formats compatible with automated processes. Our comprehensive testing capabilities validate performance under conditions matching service environments.

From initial material selection through testing and production support, our engineering team partners with clients to achieve reliable thermal protection.

Contact Electrolock today to discuss how heat-resistant electrical tape solutions can prevent thermal failures in your critical applications.