Backed by federal directives and increasing consumer interest, Electric Vehicle (EV) sales are expected to rise dramatically over the next decade. But EVs need vast quantities of energy in order to function. This energy is stored in high-voltage batteries that must have perfect electrical insulation to function correctly and as such, battery insulation sleeving is needed more than ever in this industry.

The long-term forecasts for new EV sales in the US through 2030 cite an expected strong growth curve. For example, approximately 29.5% of all new car sales in 2030 are expected to be EVs compared to the roughly 3.4% seen in 2021. This means a jump from about 500,000 new EV sales in 2021 to around 4.7 million in less than a decade.

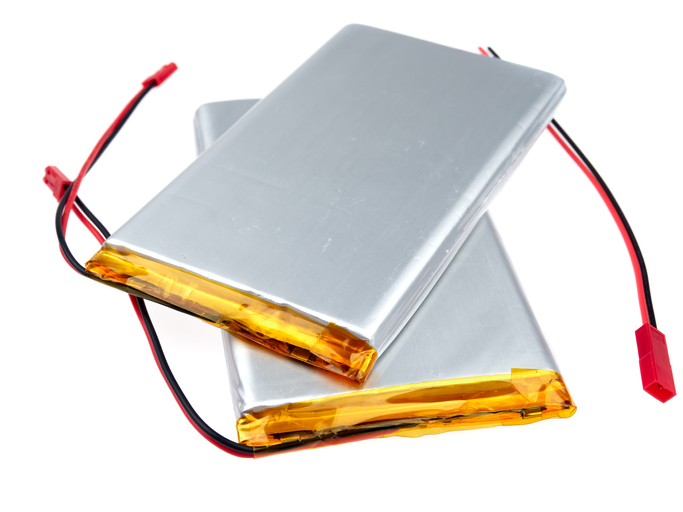

The power for EVs comes from batteries, which are typically a combination of three distinct units nestled inside one another — individual cells, groups of cells contained within a module, and the battery pack. The cells are the core of the battery as they concentrate the substances that are used to produce electrical energy. They are high-performing, rechargeable accumulators, and often are Lithium-ion, Lithium-ion polymer, or Lithium-metal polymer in type.

An EV needs a thousand times more power to operate than your everyday smartphone. So while both an EV and a phone may use a similar type of battery, many more are needed in the battery design for an EV. These cells are grouped into different modules to better protect them and make their replacement easier in the event of a breakdown.

The battery pack gathers the modules together with a cooling system and is managed by a Battery Management System (BMS), which controls the state of the battery as a whole — the unit’s temperature, voltage, and intensity among other factors.

Outside the cell insulation, like battery insulation sleeving, is critical for the continued safe and ideal operation of batteries used in these and similar applications. Battery sleeving helps ensure each cell contained in a module is protected from other cells in that enclosed environment.

4 Battery Insulation Sleeving Options

When exploring battery insulation sleeving or pouches, dielectric protection or protection against thermal runaway is a primary focus. Guarding against thermal runaway is of particular interest in the EV industry, and Electrolock has written before about specific solutions in that area. But here we’ll be examining outside the cell dielectric protection provided by sleeves, pouches, and bottom and side edge seals. Below are four heat shrink tubing sources that offer the dielectric protection needed for use in battery insulation.

PET Layflat Tubing 740 HS

This lineal seal tubing comes as heat shrink sleeves with an extremely thin wall that provides both dielectric protection and physical toughness. The 740 HS is composed of a one-side, anti-static treated modified polyester (PET) film that is clear in color but can be printed on or colored. Formed into tubing, 740 heat shrink sleeves shrink quickly — roughly in 10 seconds at 100ºC — and uniformly around cylindrical shapes.

740 linear sleeves are available in an array of diameters and lengths and can be designed to suit machine and process requirements.

PET Layflat Tubing 800 FRC

Another lineal seal tubing solution, 800 FRC heat shrink sleeves also have an extremely thin wall and provide sleeving that offers dielectric protection and physical toughness. This tubing features a one-side, anti-static treated modified PVC film. Like the 740 HS, the 800 FRC is clear but can be printed or colored and shrinks quickly — again in 10 seconds at 100ºC — and uniformly around multiple shapes.

800 FRC linear sleeves come in a variety of diameters, lengths, and widths, and can likewise be designed to fit machine and process requirements.

Heat Shrink Spiral Wound Tubes

Heat shrink polyester sleeving is used as a protective cover against abrasive or chemically harsh environments while also offering high dielectric protection, good tensile strength, and excellent chemical resistance. This sleeving will shrink in length and diameter when subjected to oven temperatures above 300ºF or by use of a heat gun or similar heating device.

Heat shrink polyester sleeving can be produced to your required diameter, wall thickness, and length. The normal diameter range is 0.096” to 3.00” with wall thickness ranging from 0.002” to 0.006”. Custom colors or striping are available on request.

Continuous Heat Shrink Spiral Wound Tubes

This product includes all the essential elements of heat shrink polyester sleeving, including dielectric protection, chemical resistance, and tensile strength with the added benefit of ease of application in automated processes. Like its counterpart, it too will shrink in length and diameter when heated to temperatures above 300ºF.

This is our standard spiral wound tubing supplied on continuous rolls, up to 2,000 feet long, that can be used for automated assembly processes.

Achieve Essential Battery Insulation Sleeving with Electrolock

Working with an experienced, trusted partner for battery insulation sleeving maximizes the chances for success in a specific application and minimizes the risk for delays, material loss, and downtime once implemented. Electrolock, Inc. has extensive expertise in analytical testing and designing solutions to find the ideal solution for your specific application.

Further engineering assistance is provided after the battery insulation sleeving is designed. Electrolock has full in-house testing capabilities to validate all the performance requirements. As your partner, our team will be present at your facility during trials to ensure the performance of the material with your application.

Electrolock has produced premier custom insulation products, including the use of many spiral wound tubing materials, for the high voltage electrical, thermal insulation, and battery industries for more than 60 years. We have deep experience in working with any material to solve insulation challenges.

Electrolock’s focus has always been on creating bespoke — unique, tailored to each client — answers to service the most technically demanding requests. So you won’t simply pick a product from a catalog; you’ll work with Electrolock’s team to create a custom-designed answer to your particular problem.