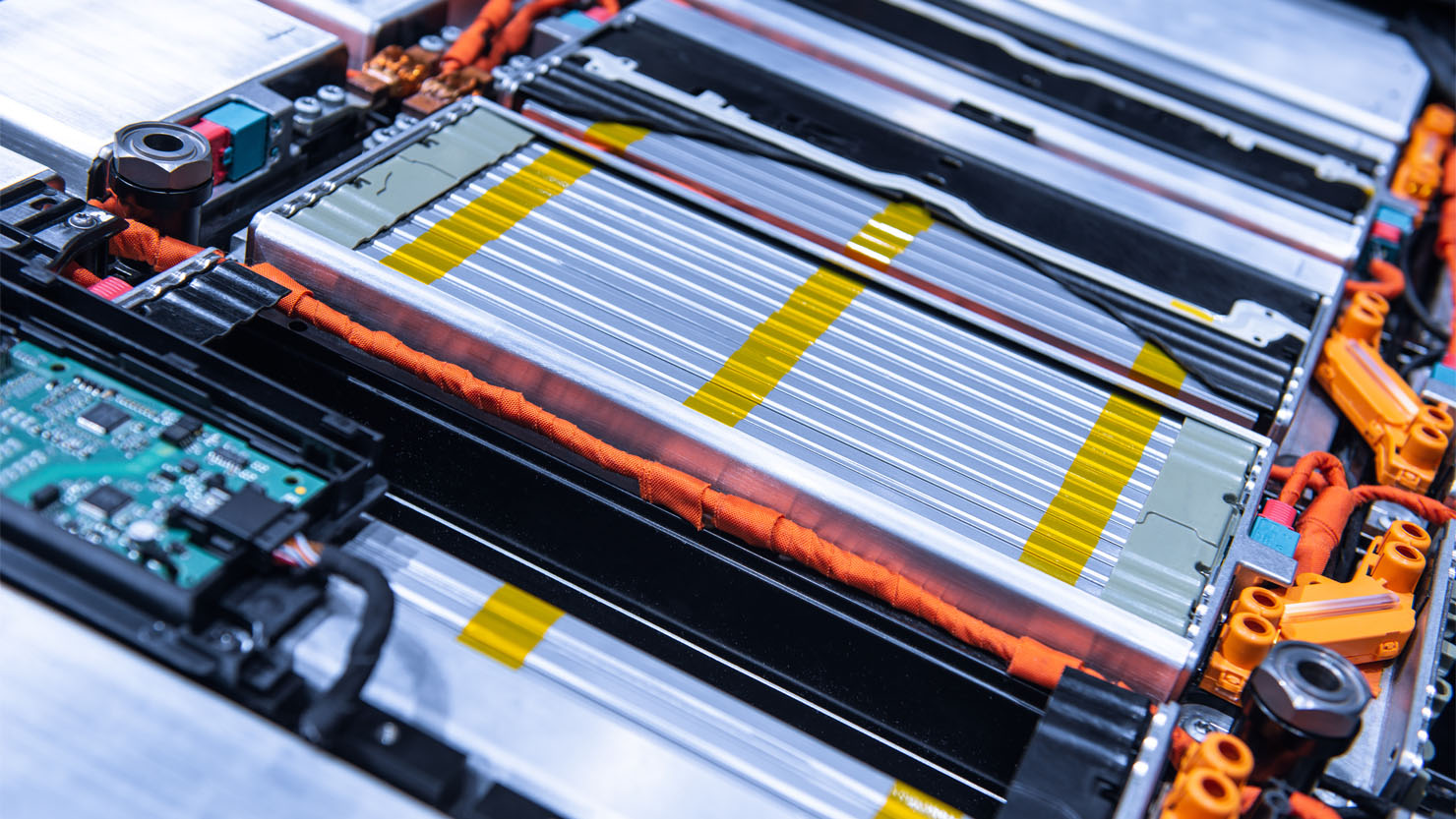

Thermal runaway has emerged as the greatest safety concern in the battery industry today. As such, battery-pack thermal runaway protection has become more important as automotive, air and marine vehicles convert to electrification.

The push for the electrification of vehicles has created a rapid acceleration of the use of Lithium-ion (Li-ion) batteries and is expected to expand the market in this realm to more than $9 billion by 2024 with a projected compound annual growth rate of 34%.

Given the expected growth in the use of Li-ion batteries, the industry is continuing to focus attention on measures designed to reduce any potential for dangerous thermal runaway conditions. Thermal runaway events are particularly dangerous for Li-ion batteries, given the notorious nature of combating fires involving them.

What is Thermal Runaway?

In the simplest terms, thermal runaway begins when the heat generated within a battery exceeds the amount of heat that is dissipated to its surroundings. If the cause of the excessive heat creation is not remedied or curtailed, the condition will worsen. As the internal battery temperature rises, the battery current will also rise — which in turn causes more heat. This results in a domino effect, and thermal issues in a single cell can begin to affect other batteries in close proximity (or part of the same pack). Once underway, thermal runaway is difficult to control and rein in.

Whether caused by defects, mechanical failures from damage, or improper operation of the system — such as storing batteries in a climate with temperatures outside the recommended range — thermal runaway will eventually drive up temperature and pressure until the battery cell ruptures. If left unchecked by built-in system protections or a Battery Management System (BMS), thermal runaway can cause a fire in affected and adjacent cells and send a bad situation into dangerous or disastrous territory.

Given the nature of battery construction, with extremely limited space for insulation protection, what are the best options for reducing cell-to-cell or module-to-module flame spread? How can the extreme heat from one cell be limited in spreading to the adjacent cells or other modules in the pack? How do you stop the chain reaction of thermal runaway once a single cell vents or ruptures?

Battery Thermal Runaway Insulation Solutions from Electrolock

Electrolock supplies various thermal runaway insulation materials that limit the spread of flame and heat during a thermal runaway event. As with all of our battery insulation material choices, our engineers try to understand the requirements of your specific battery pack and try to choose the best options for testing in the limited space available.

These materials can be a combination of flame and thermal barriers or strictly a thin wall, flame resistance part. After you test and approve the material options, we can provide the finished parts fabricated to the required dimensions. Electrolock has a half-dozen specific solutions using Pyrel-Therm and Pyrodox, a pair of thermal protection materials.

- Go-Therm Thermal Runaway Barrier– This highly flexible, silicone-based barrier is designed to be used as an interior lining of the battery case. It offers superior performance to protect the pack from the ejecta and flame caused by thermal runaway. GO-Therm is designed to be a flexible option to rigid mica plate. GO-Therm Battery Pack Thermal Runaway Barrier can be used to line the interior of a battery pack or can be used as a thermal runaway barrier between prismatic cells in a module. Parts can be fabricated to size and are available with a pressure-sensitive adhesive on one side.

- Pyrel-Therm EIG 1000 — This thin high-temperature thermal insulation material is designed to meet extreme heat environments with excellent thermal resistance, extremely low shrinkage, low thermal conductivity at high temperatures, and excellent compression resistance. EIG 1000 is available in master widths up to 1016 mm as well as custom widths and punched shapes.

- Pyrel-Therm ES 1100 — This material mirrors many of the benefits of EIG 1000 — tremendous thermal resistance, low shrinkage, and low thermal conductivity — with the added bonus of excellent mechanical properties. ES 1100 is available in master widths up to 1220 mm as well as custom widths and punched shapes.

- Pyrel-Therm RMC Mica Heat Shield — Designed to meet the demands of extreme heat environments, it exhibits a very low heat transfer profile and serves as an effective dielectric and gas barrier. RMC Mica Heat Shield is available in master rolls up to 1 meter wide or in custom slit or punched parts.

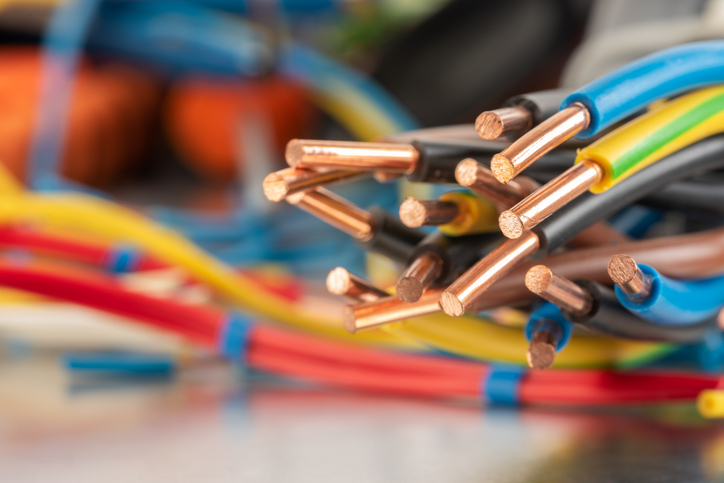

- Pyrodox GP 500 Mica Cable Tape — This is a special heat-treated phlogopite mica cable tape with a silicone binder and fiberglass backing. The tape is engineered to withstand extreme electrical and thermal overloads as well as high moisture environments, which permits its use in cables having extended fire survival time. Applications include fire survival for control and power cables, mass transit, aircraft, oil well, thermocouple, appliance wire, and shipboard cables. Tape is provided in slit pads or traverse packs in lengths according to the customer’s request.

- Pyrodox HP5 Mica Plate — This mica plate is designed for high-temperature insulating applications and comes with excellent mechanical, electrical, and thermal characteristics including a flame classification of UL 94 V-0. Standard thickness is .1mm-1.9mm, and standard sheet sizes include 1000mm x 600mm, and 1000mm x 1200mm. Both phlogopite and muscovite versions are available.

Electrolock is Your Battery Insulation Expert

Electrolock has been engineering solutions for high-voltage electrical, battery, and thermal insulation industries since 1957. Electrolock’s focus has always been on creating bespoke — unique, tailored to each client — answers to service the most technically demanding requests. You won’t simply pick a product from a catalog; you’ll work with Electrolock’s team to create a custom-designed answer to your particular problem.

Our expertise is trusted by many customers across many fields, including the U.S. Military, which has relied on our battery thermal runaway insulation to safeguard the many battery needs of active service members.